A detailed classification of common cylinder types and their characteristics

1. Classification according to structural characteristics

Pen cylinder (mini cylinder)

The material is stainless steel or aluminum alloy, compact structure, low price, suitable for high-frequency use scenarios (such as electronics, medical industry).

It must be installed with a magnetic switch and floating connector, and the stroke must be reserved.

thin cylinder

Square cylinder block design, can be directly installed in the fixture, no additional accessories, but need to be used with guide elements.

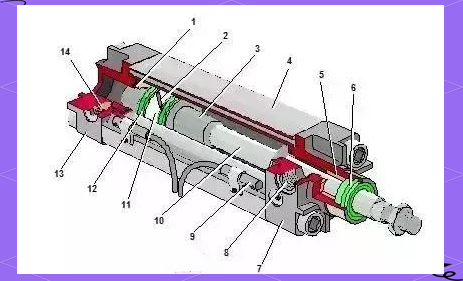

rodless cylinder

Reciprocating motion through mechanical or magnetic coupling saves space and is suitable for long travel scenarios (such as semiconductor manufacturing), but avoids bending caused by direct force.

twin cylinder

It is composed of two thin cylinders in parallel, strong resistance to lateral load, and the front anti-collision pad can adjust the stroke.

2. Classification by function and guiding characteristics

guide rod cylinder

It is divided into linear bearing type (low friction) and copper sleeve type (high load), with guiding function, suitable for pushing, clamping and other scenes.

slide cylinder

The use of cross ball guide rail, high guiding accuracy, strong load capacity, but the cost is high.

air jaw

Including parallel, swing, rotation and other types, two-way grasp and repetition accuracy is high, often used in manipulators.

swinging cylinder

Rack and pinion type, used for object rotation or turning.

3. Other special types

rotary lower cylinder : the compact structure to achieve rotary compression action.

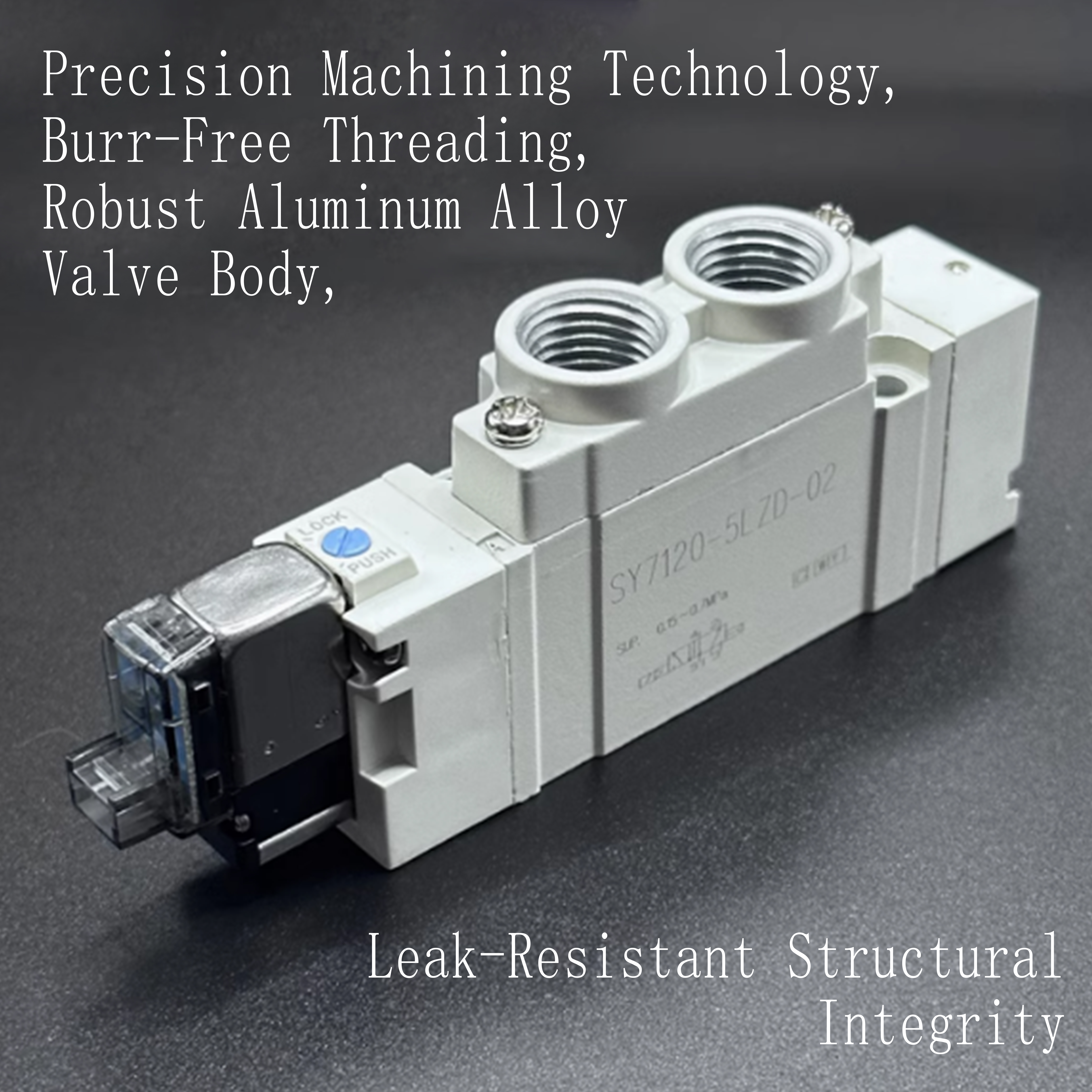

standard cylinder : simple structure, strong versatility, widely used in material handling and assembly line.

Note : Space, load, accuracy, cost and other factors should be considered comprehensively when selecting the type. For example, pen cylinder is preferred in high-frequency scenes, and guide rod or slide cylinder is required to support high load.