precise explanation of commonplace Faults and answers of Solenoid Valves

Fault phenomenon

remedy method1️⃣

1、The solenoid valve doesn't work after being powered on

first of all, take a look at whether or not the wiring is unbroken. subsequent, verify whether or not the coil is damaged. thru giving the command to open or near the solenoid valve, concentrate carefully to look if there can be any sound of motion. If there's no sound, the trouble may also lie inside the circuit or the coil. similarly inspect the wiring to affirm whether there are any negative contacts, open circuits or quick circuits. If the circuit is ordinary, it might be that the solenoid valve coil is burned out. The wiring wishes to be removed and measured with a multimeter. The reasons for the coil burning out may encompass moisture most important to a decline in insulation typical performance, overly difficult springs causing immoderate response pressure, and inadequate coil turns resulting in insufficient suction pressure, and so forth. the burned coil wishes to be replaced.

The solenoid valve cannot be opened after being powered on

check whether or not or no longer the valve cover screws are tightened. If the valve cover gasket has been modified nowadays, it's far essential to verify that the thickness of the gasket is suitable and the tightness of the screws is constant. on the identical time, take a look at whether or not or now not the valve middle is caught. If there is a pilot valve, moreover take a look at whether or now not the valve port of the pilot valve is blocked.

The solenoid valve cannot near after power failure

in addition, it's far necessary to check whether or not or now not the valve middle is stuck or the pilot valve port is blocked. If the solenoid valve can't close to tightly, it's miles crucial to in addition take a look at whether or now not the valve middle sealing gasket is intact and whether or not the valve seat is unfastened.

For valve middle jamming or blockage faults, cleaning is an powerful solution. it is able to be cleaned with gas or water and then dried with compressed air. whilst disassembling the solenoid valve, make sure to take into account the gathering of each issue in truth to avoid mistakes at some point of reassembly and inflicting new problems.

The strategies for trying out the great of solenoid valves

First, introduce the managed medium into the solenoid valve, which can be a pressurized liquid or gas (which includes air), and the strain charge should be set inside the running stress type of the solenoid valve. subsequent, strength at the solenoid valve coil. If the managed medium can gather state adjustments from on to off or from off to on, the solenoid valve is in accurate situation. otherwise, there is probably a malfunction.

not unusual faults of solenoid valves encompass brief circuits or open circuits inside the coil. A multimeter may be used to diploma such faults. If the resistance cost processes zero or infinity, it shows that there's a brief circuit or open circuit hassle inside the coil. however, sometimes, even supposing the size consequences show that the resistance price is regular, it cannot be absolutely decided that the coil is in accurate situation. consequently, we although want to behavior the very last test: carry a small screwdriver near the metallic rod surpassed via the solenoid valve coil. If magnetism may be felt after being powered on, the coil is in pinnacle circumstance. in any other case, the solenoid valve coil wishes to be replaced.

2. Plug/socket troubles

If the solenoid valve is prepared with a plug and socket, troubles with the metal spring of the socket or incorrect plug wiring (which includes mistakenly connecting the strength wire to the ground cord) may additionally arise, resulting within the energy not being brought to the coil. it's miles endorsed to plug inside the plug and then tighten the fixing screw. make sure that the solving nut is likewise tightened after the coil is set up to the valve center stem. If the solenoid valve coil plug is prepared with a power indicator slight, it needs to be associated efficiently while pushed by means of DC power; otherwise, the indicator mild will not mild up. on the same time, be careful not to mix power plugs with strength indicators of various voltage ranges and moderate-emitting diodes to keep away from burning out the mild-emitting diodes or short circuits inside the energy supply. If there is no strength indicator light, the solenoid valve coil does not want to differentiate the polarity.

treatment approach:

accurate wiring mistakes and repair or update plugs and sockets.

3. Valve center failure

If there may be no response at the same time as the manual button of the solenoid valve is pressed under ordinary medium stress, it suggests that the valve center has been damaged. it is crucial to check whether there are any troubles with the medium, which incorporates water accumulation inside the compressed air or impurities inside the liquid medium, and remove them. If the problem persists, you may strive repairing or converting the valve middle, or directly replace the entire solenoid valve.

Fault Phenomenon 2️⃣:

If the coil is the true one and the magnetic subject is normal whilst powered on, but the solenoid valve despite the fact that does not perform, it is able to additionally indicate that the valve center is broken. At this thing, it's also encouraged to repair or replace the valve center, or right away replace the whole solenoid valve.

regarding the upkeep of solenoid valve our our bodies, because of the wide sort of sorts, particular strategies will now not be elabonotabled proper here.

Faults and Troubleshooting of Solenoid Valves

①. The solenoid valve does no longer work after being powered on

initially, it's miles essential to test whether or not or no longer the strength connection is right and make certain that the wiring and connectors are successfully connected. subsequent, check whether or no longer the electricity supply voltage is inside the normal working variety. If there can be a problem, make changes. at the equal time, take a look at whether or not or no longer the coil is de-soldered or quick-circuited. If there is a trouble, the coil wants to be re-soldered or modified. further, it's far vital to affirm whether or not or not the working stress distinction is appropriate. If it is not, changes ought to be made or the corresponding solenoid valve replaced. If the fluid temperature is simply too excessive, a suitable solenoid valve should also be replaced. similarly, if the precept valve center and the transferring iron middle are jammed by impurities, they want to be wiped easy and the seals modified. at the same time, filters must be mounted. similarly, if the liquid viscosity is surely too excessive, the frequency is virtually too immoderate, or the product's lifespan has expired, it is able to additionally motive problems. In such cases, the corresponding product should get replaced.

②, the solenoid valve can't be closed

If the solenoid valve fails to close, it could be due to the harm of the sealing factors of the precept valve middle or the iron moving center. for the time being, they should get replaced right now. at the identical time, it is important to affirm whether or not or no longer the fluid temperature and viscosity are too excessive. If there can be a trouble, replace the right solenoid valve. If impurities enter the solenoid valve and cause the valve center or shifting iron middle to get stuck, the relevant additives need to be very well cleaned. similarly, the expiration of the spring's service lifestyles or deformation may also moreover affect the closing of the solenoid valve. proper now, the spring need to get replaced. further, blockage of the throttle hollow or stability hole also can purpose troubles, so the relevant factors want to be wiped clean in a well timed way.

③. other occasions

If the solenoid valve has internal leakage, it's miles essential to test whether or not or now not the sealing factors are intact and whether or not or no longer the spring meeting is correct. For outside leakage issues, it is critical to confirm whether or no longer the connection elements are loose or the seals are damaged, and take corresponding measures to tighten the screws or update the seals. If noise takes region while powered on, it could be due to unfastened fasteners at the pinnacle. proper now, the relevant components want to be tightened. on the identical time, it is important to confirm whether or not or now not the voltage fluctuation is within the allowable range and adjust it to the regular voltage. in addition, if there are impurities or unevenness issues at the middle's bonding ground, the relevant additives ought to moreover be cleaned or changed in a timely manner.

On-internet site on-line short technique for judging the 2927099c7129e5e67b031f9eb65b6349 of solenoid valves

①, check whether or not the electromagnetic coil of the solenoid valve is faulty.

on the DCS, offer the sign to open or close to the two-position valve to have a look at whether the solenoid valve is energized or not. commonly, it may be judged by means of listening to the sound on internet site. If no sound may be heard, there might be a hassle with the coil. next, we need to further decide whether or not the solenoid valve itself is defective.

②, if the coil is ordinary, then the problem may additionally lie with the solenoid valve itself.

At this factor, we will use a single man or woman to modify from 1 to zero at the guide adjustment role and attempt to open the valve. If it is able to be efficaciously opened, it shows that the trouble lies within the coil. sincerely replace the coil. If it cannot be opened, the solenoid valve needs to be disassembled to check whether or not the valve center is stuck or blocked by using the use of foreign places particles. whilst cleansing, CCL4 or exceptional organic solvents have to be used. If the on-website online conditions are limited, gas or water additionally can be used as substitutes. After cleaning, it need to be dried with device air. while disassembling, make certain to take into account the collection of every factor honestly to keep away from reassembling wrongly.

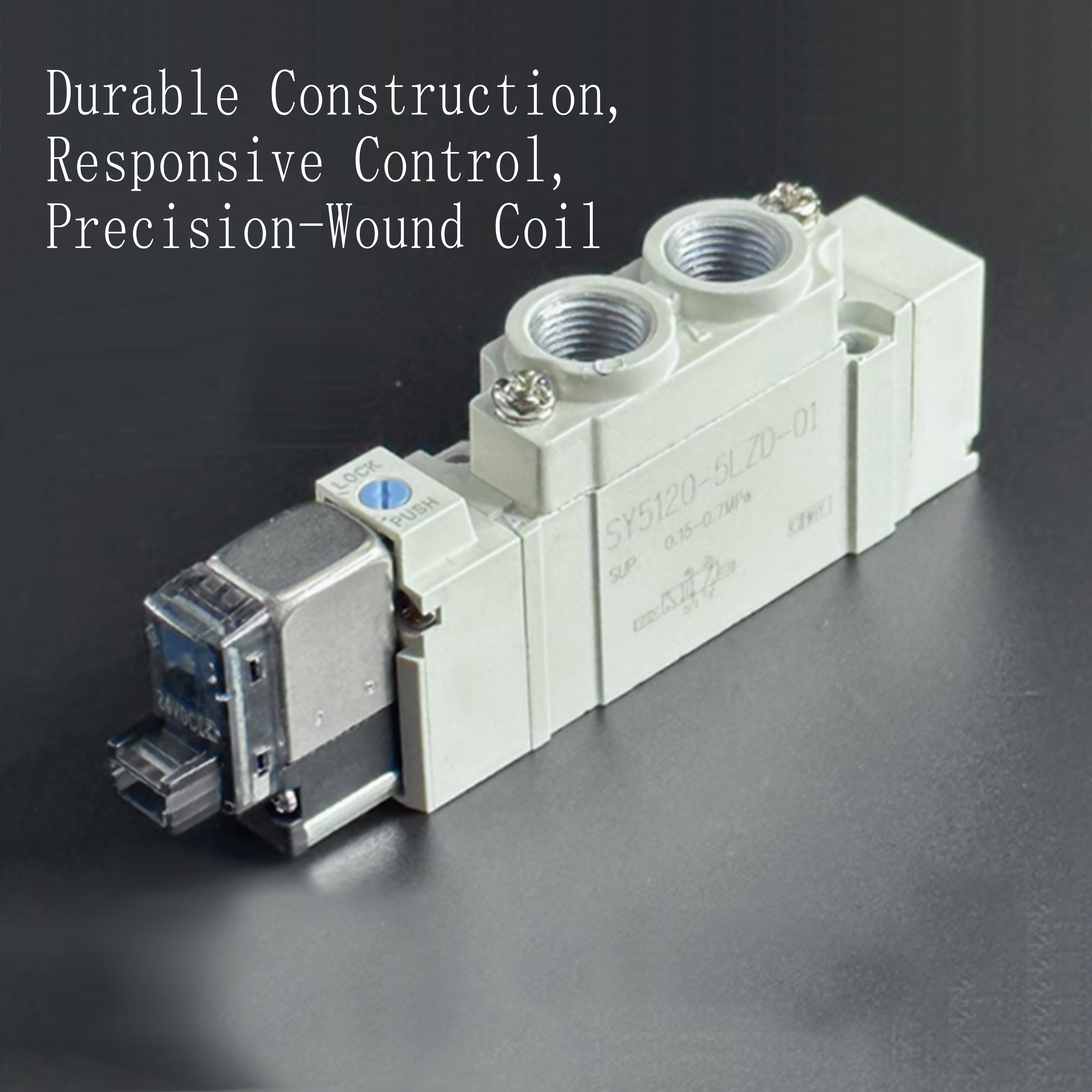

The exceptional of an electromagnetic valve specifically is based upon at the coil and the valve frame.

throughout the check, we will discover a 24V power deliver and connect it to the coil to have a examine if there can be any noise. If there is a noise, it shows that the coil and the valve middle are normal and can be engaged commonly. next, check for any air leakage. If there can be an air deliver, right now join it for judgment. If there's no air supply, block the air outlet and blow it together along with your mouth to test. in addition, the inspection of the coil also can be performed via a multimeter.

After the solenoid valve is powered on, unplug the plug and use a multimeter to degree whether or not there can be electricity.

at the same time as the solenoid valve is energized, convey a thin steel wire near the coil to look at if there's any suction pressure.

time and again power on and rancid. Use a thin Allen wrench to softly tap the copper-coloured "small pit" at the solenoid valve shaft to experience if it is able to be typically engaged and eout.

in addition, the state of affairs of the solenoid valve additionally may be judged with the aid of detecting its on-off popularity. The specific technique is to supply strength to the solenoid valve coil even as the control medium of the solenoid valve (which consist of pressurized liquid or gasoline) is brought, and look at whether or not or not the manage medium can attain a kingdom exchange from directly to off or from off to on. if so, the solenoid valve is ordinary. in any other case, there is probably a malfunction.

commonplace faults of solenoid valves encompass brief circuits or open circuits inside the coil. whilst undertaking the take a look at, first diploma its on-off popularity and resistance price with a multimeter. If the resistance price is ordinary, there may be a brief circuit or open circuit. but, every so often a regular resistance cost does now not assure that the coil is actually in well circumstance. therefore, a very last test is wanted: place a small screwdriver close to the solenoid valve coil. If it feels magnetic after being powered on, the coil is in incredible circumstance. in any other case, the coil desires to be replaced.

in addition, problems with the plug/socket also can purpose the solenoid valve to fail to work well. consequently, while connecting the plug and socket, ensure the solving screws are tightened to save you the power from now not accomplishing the coil. at the identical time, if the solenoid valve coil plug is prepared with a mild-emitting diode electricity indicator slight, the electricity supply should be related efficaciously even as the usage of the solenoid valve; otherwise, the indicator light might not mild up. further, it's far vital to keep away from swapping the strength plugs with electricity signs of various voltage ranges and mild-emitting diodes to save you issues including the burning out of moderate-emitting diodes or energy brief circuits.

If there can be no strength indicator light, the solenoid valve coil does not want to distinguish polarity (not like transistor time relays and intermediate relays for DC coil voltage, the latter of which want to differentiate polarity). If it is observed that the solenoid valve can't work properly, first check whether or not the wiring is accurate, and restore or update the plug, socket and specific components.

troubles with the valve center might also reason the solenoid valve to fail. as an instance, if the medium stress is regular however there may be no response even as the manual button of the solenoid valve is pressed, it shows that the valve center may be broken. At this thing, it is vital to test whether or not or now not there are any problems with the medium, which includes disposing of collected water or impurities, and trying to restore or update the valve core. If the manual button of the solenoid valve skills typically however the valve center nonetheless does now not go with the flow, it is also necessary to do not forget converting the valve center or the whole solenoid valve.

in addition, the problem that the solenoid valve fails to shut after energy failure can be because of a variety of motives. for instance, if the arrow of the solenoid valve body is inconsistent with the course of fluid float, it desires to be reinstalled to preserve consistency. If the valve can't be closed tightly because of particles blockage, the solenoid valve and the filter out show need to be wiped smooth. problems in conjunction with jamming of the shifting iron middle, spring and foremost valve core, or harm to the sealing elements also need to be repaired or changed hence.

while coping with solenoid valve troubles, a cautious inspection ought to be finished and the corresponding coping with steps want to be accompanied. If the trouble is complex or unsolvable, it's far recommended to are looking for the help of specialists.