a way to modify the pneumatic cylinder while the extension and retraction is not clean and stuck

①. reasons for the unsmooth extension and retraction of pneumatic cylinders and their jamming

there are many reasons for the pneumatic cylinder not extending smoothly or getting caught, such as getting older of the cylinder seal and dirt on the internal wall of the cylinder. distinctive reasons require exceptional adjustment techniques.

②. Adjustment methods

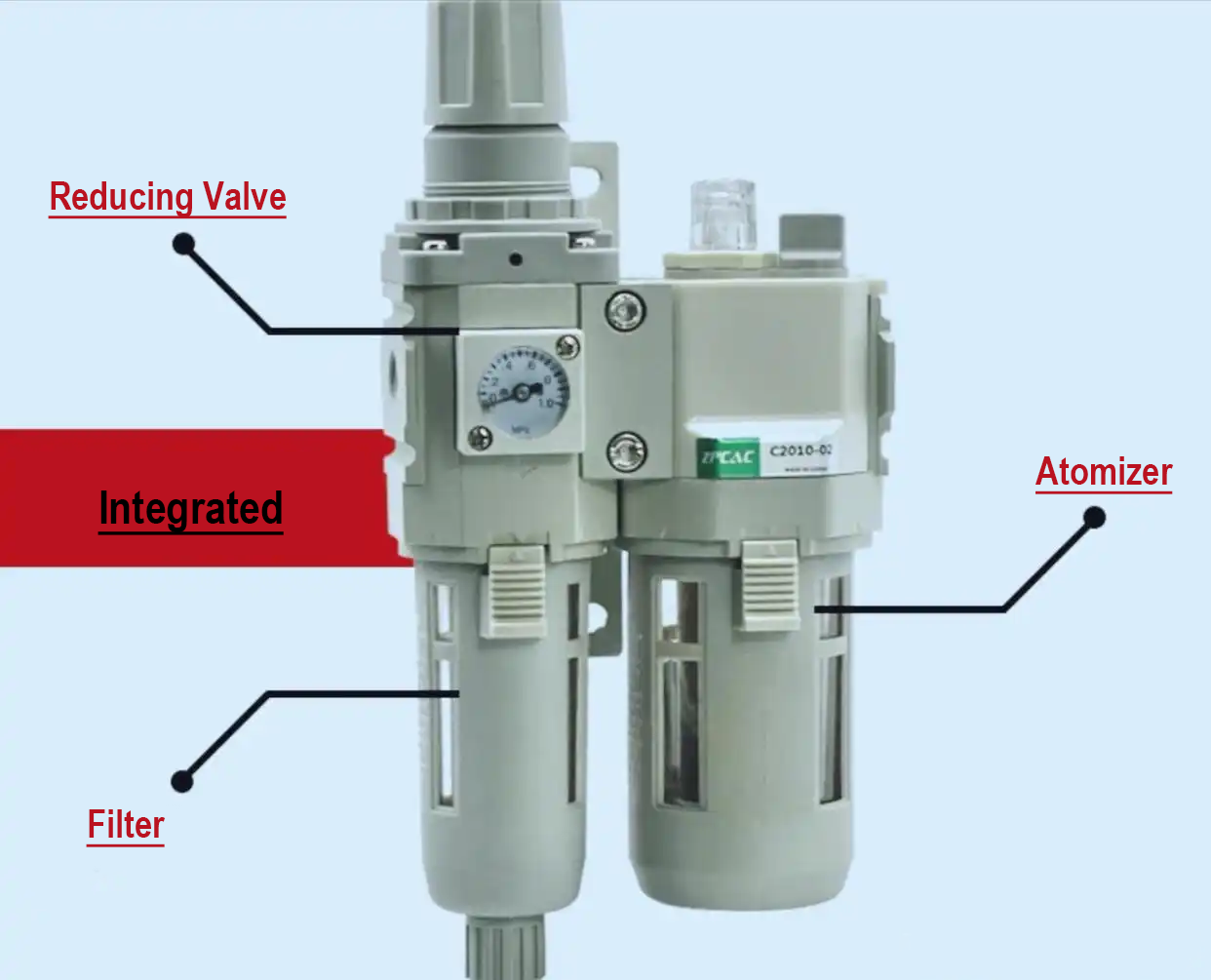

1.adjust the stress of the air supply

The operating strain of the pneumatic cylinder may be very vital. If the stress is simply too low, the extension and retraction of the cylinder turns into slow. Conversely, if the strain is too high, the extension and retraction of the cylinder becomes caught. therefore, the strain of the fuel source needs to be adjusted according to the real state of affairs.

2. easy the cylinder

Rust, dust, oil stains and different materials may additionally deposit at the internal wall of the cylinder, which may additionally cause the cylinder to get stuck. consequently, cleansing the internal wall of the cylinder is an critical approach to hold the pneumatic cylinder operating commonly.

3. update the seals

If the cylinder seal ages or wears out, it'll cause the cylinder to extend and agreement unsmoothly. right now, the corresponding seal needs to get replaced.

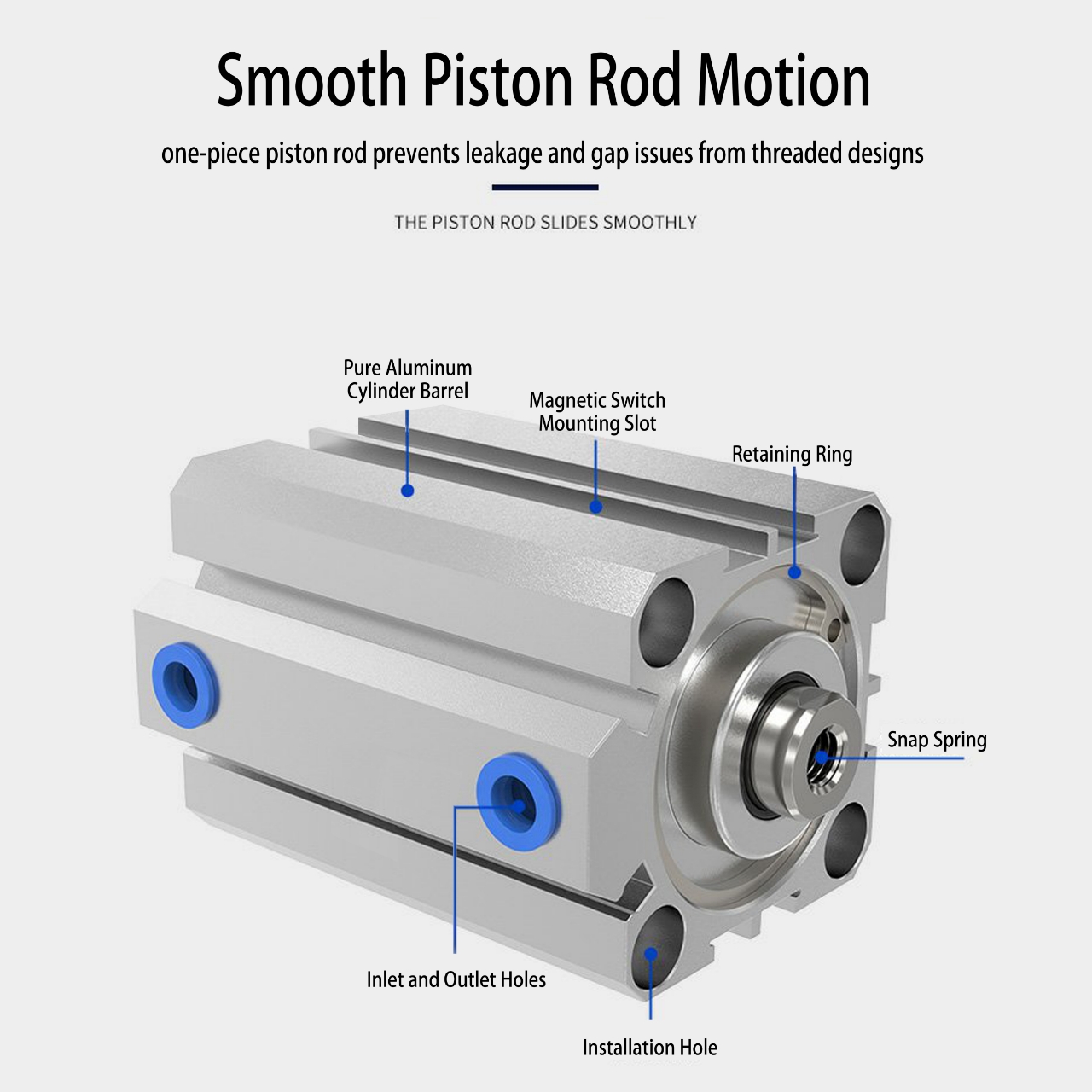

4. modify the tightness of the cylinder piston

If the piston of the cylinder is just too tight or too free, it'll motive the cylinder to increase and contract unsmoothly. consequently, it's miles vital to correctly alter the tightness of the cylinder piston in keeping with the real state of affairs.

③. Precautions

while adjusting the pneumatic cylinder, protection have to accept top priority. at the equal time, the correct adjustment approach must be decided on based totally on the precise scenario to avoid the cylinder getting greater caught due to incorrect operation.

[Conclusion]

The problem of the pneumatic cylinder no longer extending smoothly and getting caught can be caused by motives together with the strain of the air source, dirt at the inner wall of the cylinder, and the sealing parts of the cylinder. This problem can be efficiently solved by adjusting the air source pressure, cleaning the cylinder, changing the sealing parts and adjusting the tightness of the cylinder piston, and so forth., to ensure the regular operation of the pneumatic cylinder.