A pneumatic solenoid valve is an electromechanical device used to govern the waft of compressed air in pneumatic structures. Its primary characteristic is to behave as a transfer or regulator for steering air to exceptional elements of a gadget, permitting the automation of mechanical processes. here is a breakdown of its makes use of:

1. manage of Pneumatic Actuators

It directs compressed air to pneumatic cylinders or actuators, enabling motion which includes pushing, pulling, rotating, or lifting in machines.

2. Automation of machinery

widely used in computerized business gadget to manipulate techniques like packaging, assembly, or conveyor structures.

three. float path manipulate

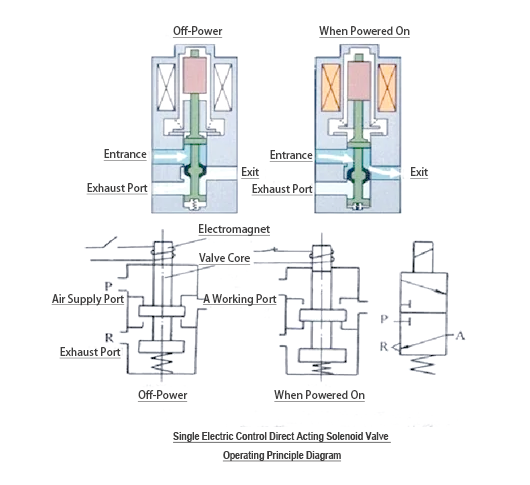

Solenoid valves manipulate the course of air go with the flow, including switching between ahead and opposite actions in pneumatic systems.

4. strain law

they could regulate the air pressure provided to various components, making sure the system operates thoroughly and successfully.

five. On/Off manipulate

Used as an on/off transfer for air float in structures like air compressors, spray weapons, or equipment that require specific manage.

6. applications in numerous Industries

automotive: Controls air brakes, suspension systems, and transmission structures.

scientific: Operates in ventilators, oxygen concentrators, and lab system.

food & Beverage: utilized in filling, packaging, and processing system.

manufacturing: helps meeting lines, robotics, and automatic tools.

the versatility, speed, and reliability of pneumatic solenoid valves lead them to essential to fashionable automated structures.