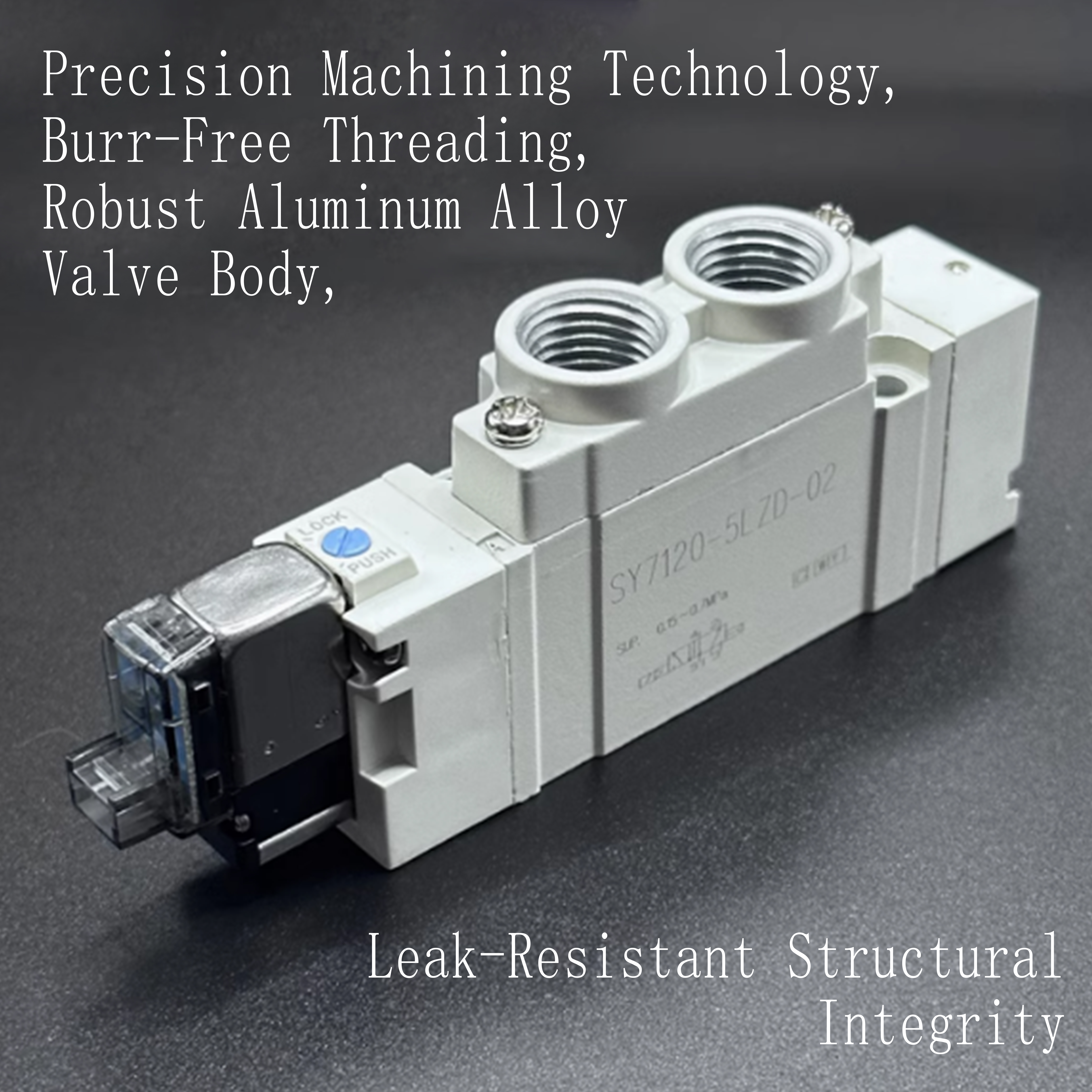

The reason of a pneumatic 5-port, -manner valve (frequently referred to as a 5/2 valve) is to govern the route of compressed air go with the flow in pneumatic systems, normally for controlling double-performing actuators like cylinders. it is designed to manage the flow of air to and from extraordinary parts of the system and is crucial for controlling the movement of actuators, which regularly want to extend and retract in a controlled way.

Key functions of a Pneumatic five/2 Valve:

control of Air float route:

The five/2 valve regulates the flow of compressed air between two working ports (A and B), switching the direction of waft among them. This movement helps direct air to an appropriate facet of a double-acting cylinder to make it increase or retract.

In position 1, air is directed to one port of the cylinder, inflicting it to increase. In position 2, air is directed to the opposite port, causing the cylinder to retract.

Double-performing Cylinder control:

A double-acting cylinder has two ports (one for each facet of the piston). The five/2 valve allows for the controlled movement of the piston in both guidelines by alternating the air circulate those ports.

while the valve is shifted to one role, it directs compressed air to one side of the cylinder to increase it.

inside the different role, it directs air to the opposite side to retract the cylinder.

hard Air:

The valve also presents exhaust ports (EXH1 and EXH2) that permit air to depart the cylinder once the favored movement has been performed. This ensures that the actuator can return to its unique role or preserve its position after the movement is finished.

Air from the prolonged aspect of the cylinder is expelled via the exhaust port, while the air at the retracted aspect is exhausted through the opposite port.

Switching between drift Paths:

The valve basically switches among glide paths:

course 1: pressure port (P) to port A (for extension) and port B to exhaust port EXH2.

direction 2: stress port (P) to port B (for retraction) and port A to exhaust port EXH1.

This guarantees that the pneumatic device can change the waft of air to obtain specific tasks, together with pushing, pulling, or positioning.

Automation and manage:

The valve is usually operated via solenoids that manipulate its movement. when a solenoid is energized, the valve shifts from one role to any other, making it critical for computerized structures wherein particular manage over the actuator's movement is needed.

it is a key thing in computerized systems consisting of robotics, conveyor belts, presses, or any machinery that calls for controlled motion.

applications:

Automation systems: used in factories and assembly lines for shifting or positioning gadgets.

Robotics: For controlling the movement of robotic hands or legs.

Packaging machinery: For controlling packaging moves like sealing, folding, or reducing.

cloth handling: In systems where materials want to be pushed or pulled the usage of air-powered cylinders.

urgent/Clamping: In programs where precise movements, like pushing or pulling an object, are required.

precis:

A pneumatic 5/2 valve serves the essential feature of controlling the route and float of compressed air in a gadget, making an allowance for the appropriate motion of double-acting cylinders. It alternates between positions to increase and retract actuators, often used in automatic structures for duties together with pushing, pulling, clamping, or positioning. The valve’s operation guarantees green and controlled motion inside the pneumatic device.