A 5/2 directional manage valve is used to control the waft path of air, water, or different fluids in a device, commonly in pneumatic or hydraulic circuits. Its number one function is to direct fluid go with the flow between one-of-a-kind elements of a machine by way of switching among two positions, allowing it to manipulate the movement of double-performing actuators (consisting of cylinders) or other devices.

Key features of the 5/2 Directional manage Valve:

flow course manipulate:

The valve can transfer the route of waft, directing the fluid from the stress supply (P) to one of the operating ports (A or B), and also to exhaust the fluid from the other working port (EXH1 or EXH2). This controls the movement of a double-acting actuator (including a piston or cylinder).

role 1: stress port (P) connects to port A, and port B is exhausted via EXH2.

role 2: stress port (P) connects to port B, and port A is exhausted via EXH1.

Actuator movement control:

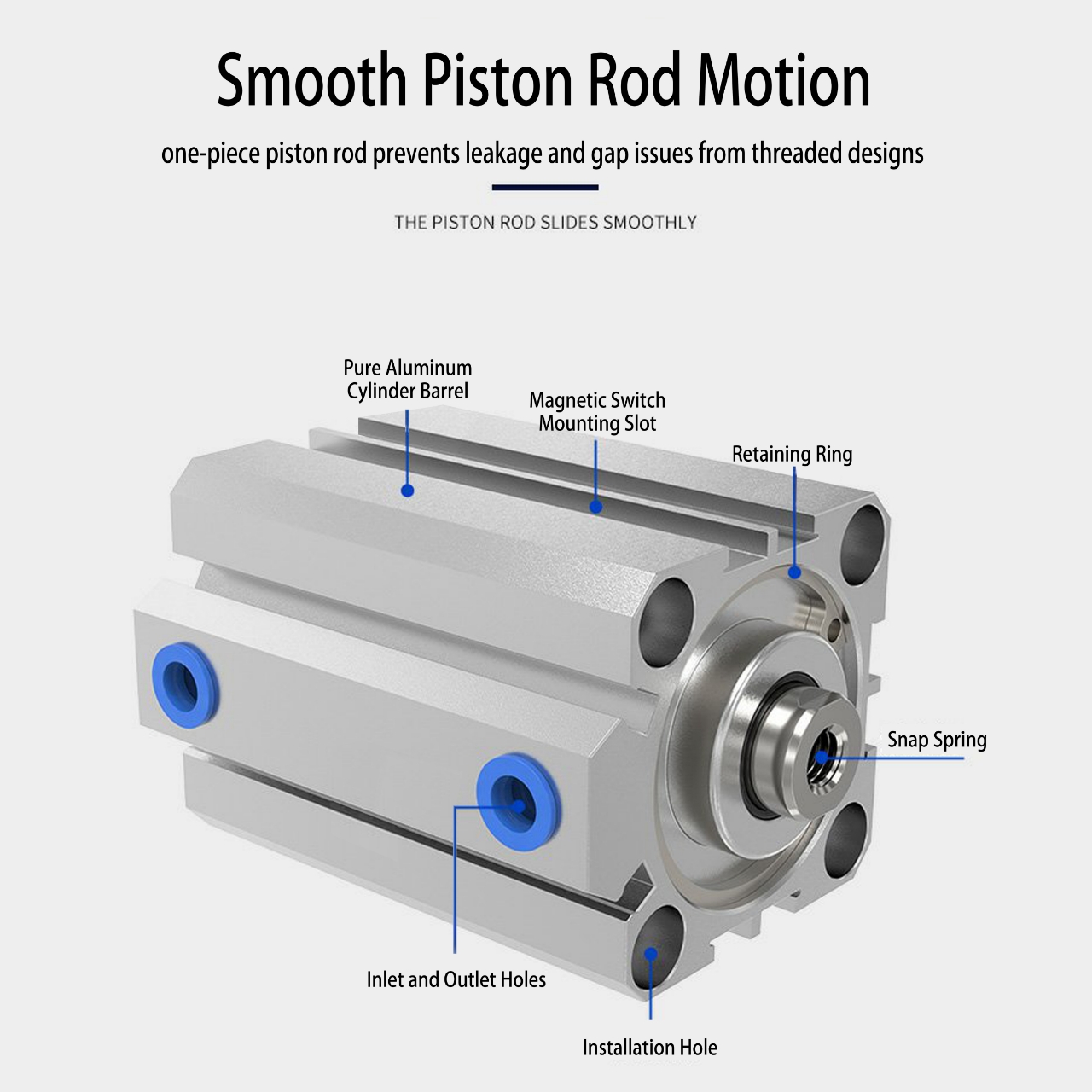

In pneumatic structures, it controls the make bigger and retract moves of a double-acting cylinder:

whilst the valve is in a single function, it allows air to circulate one side of the cylinder, causing it to extend.

while the valve shifts to the opposite function, it directs air to the opposite facet of the cylinder, causing it to retract.

Automation and safety:

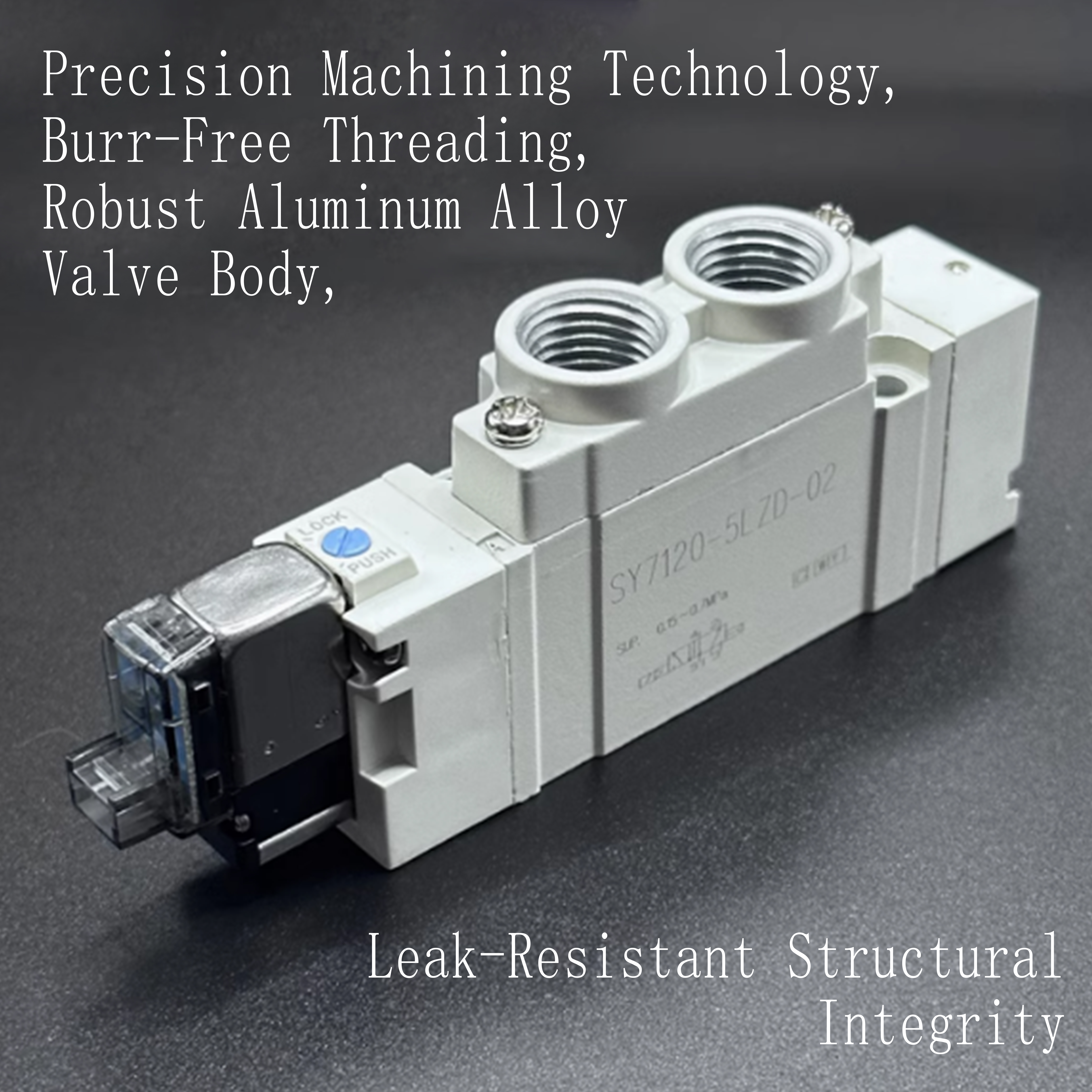

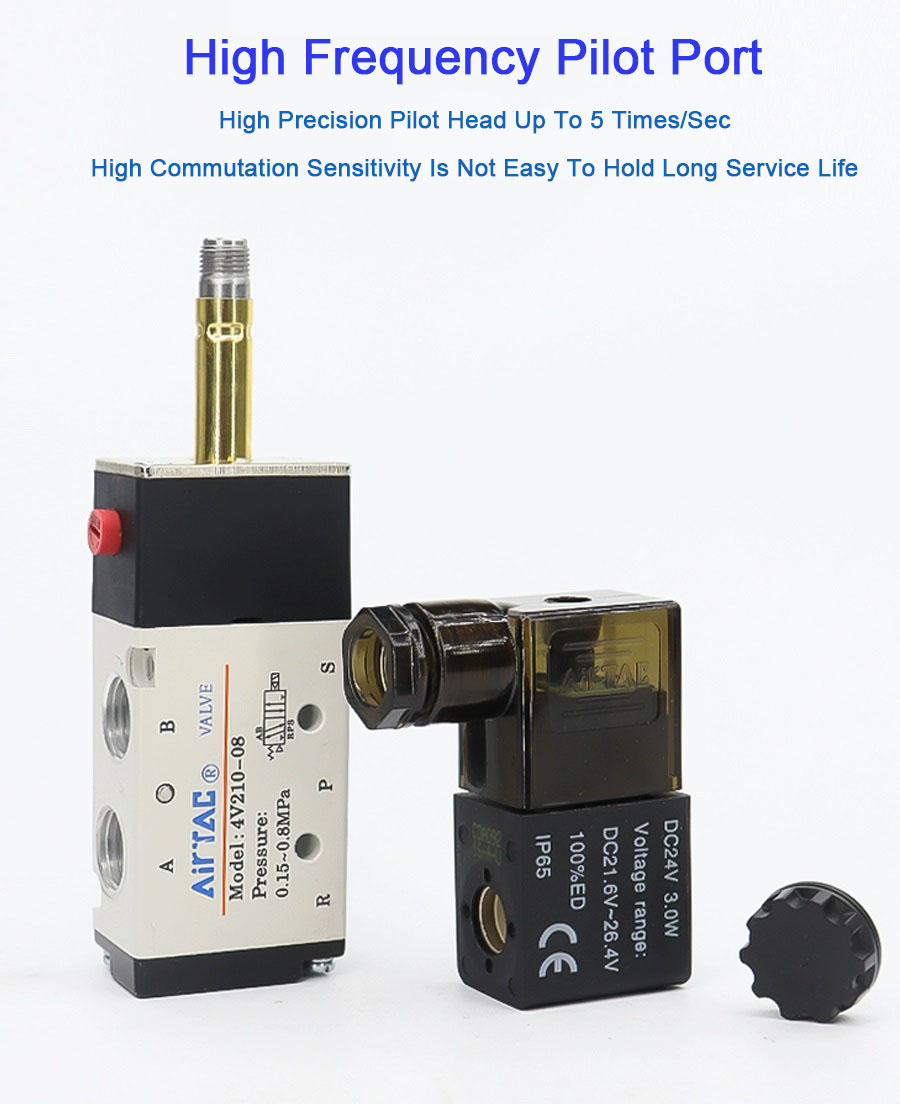

5/2 valves can be computerized via solenoids, in which electrical alerts trigger the valve to shift among its two positions. This makes it perfect for controlling machines and gadget that require unique control over their movement or motion.

It allows in making sure secure and efficient operation in automatic systems by means of presenting a reliable approach of switching fluid go with the flow.

gadget Isolation:

The valve can isolate elements of the machine by means of connecting or disconnecting the waft route. for example, when the valve is in a shifted role, it can isolate one facet of the actuator, conserving it in region.

packages:

Double-performing cylinders: not unusual in automation systems, robots, presses, and any application wherein the actuator requires each extension and retraction.

material handling structures: For controlling push/pull movements.

computerized equipment: To control the ideal operation of numerous mechanical components, frequently at the side of sensors and controllers.

summary:

The five/2 directional manage valve is more often than not used to govern the direction of fluid glide to actuators, typically in systems where double-performing cylinders are used. It shifts among two positions to manipulate whether the actuator extends or retracts, gambling a critical role inside the automation of fluid-powered structures.