Detailed Selection Explanation of SMC Finger Cylinder Support Point Opening and Closing Type Air Grippers MHC2-20D

In the field of industrial automation, the performance and reliability of cylinders are of vital importance to the entire system. The MHC2-20D pneumatic gripper launched by SMC Corporation of Japan is a typical representative of the fulcrum opening and closing type pneumatic fingers. Its design integrates high rigidity, high precision and modular features, and is suitable for scenarios such as automated assembly and robot grasping. With its outstanding performance, it has become a popular choice in the market. This article elaborates in detail from four dimensions: technical parameters, selection logic, configuration optimization, and industry adaptation.

I. Analysis of Core Technical Parameters

1.Mechanical structure and driving characteristics

Dual-piston drive: It adopts a symmetrical dual-piston structure. Compared with the single-piston design, the clamping torque is increased by 40%, reaching 0.70N·m (@0.6MPa air pressure), suitable for grasping precision workpieces with a weight of ≤500g.

Integrated guide rail design: Equipped with high-precision linear guide rails, the repeat positioning accuracy reaches ±0.01mm, which is superior to the industry average (±0.03mm), and can meet the micron-level precision requirements for electronic component mounting and other applications.

Variable throttling control: The cylinder body integrates a flow control valve, which can adjust the opening and closing speed (0.1-0.5m/s) through a knob, meeting the grasping requirements of different workpieces. 14

2. Pneumatic parameters and environmental adaptability

| Parameters | Numerical range | Industry comparison |

| Work pressure | 0.1-0.6 MPa | It covers low-pressure (0.1-0.3MPa) and medium-pressure (0.4-0.6MPa) scenarios |

| Ambient temperature | - 10 ~ 60 ℃ | It is higher than ordinary air grippers (-5 to 50℃) and can adapt to high-temperature environments such as industrial ovens |

| Response time | 15-25ms | Fast response (such as semiconductor wafer handling) |

| Lifespan | ≥5 million cycles | It is 2.5 times that of a common pneumatic claw (2 million times) |

3. Interface and installation compatibility

Gas path interface: Standard equipped with M5×0.8 internal thread, supports quick couplings (such as KQ2 series), and needs to be connected to the G1/8 interface through a conversion joint 14.

Installation methods: Three modes are provided, namely base installation (standard type), flange installation (optional), and horizontal installation (with locating pins), to adapt to different end structures of mechanical arms.

Ii. Selection Decision Tree

1. Demand diagnosis

Load capacity: If the grasping weight is greater than 500g, it needs to be upgraded to MHC2-25D (clamping torque 1.2N · m) or the parallel air claw MHL2 series should be selected.

Precision requirement: If the repeat positioning accuracy needs to be ≤±0.005mm, it is recommended to use a precision guide rail module (such as LM slider).

Environmental conditions: Dust covers (model suffix -X1083) should be selected for dust environments, and the non-lubricated version (-Z73) should be chosen for cleanroom scenarios.

2. Configuration optimization

Magnetic switch: Optional D-M9P/Z (NPN/PNP type) is available to achieve gripper position detection, with a signal transmission distance of ≤ 5 m14.

Jaw material: Standard aluminum alloy jaws are suitable for ordinary working conditions. If corrosion resistance is required, stainless steel jaws (-S) or POM resin jaws (-X1862) can be selected.

Buffering design: Built-in rubber buffer pads. If higher buffering performance is required, an external hydraulic buffer (such as RB series) can be connected.

3. Cost control

Economic solution: The single-acting version (MHC2-20S) is adopted, reducing the cost by 20%, but it only supports spring return.

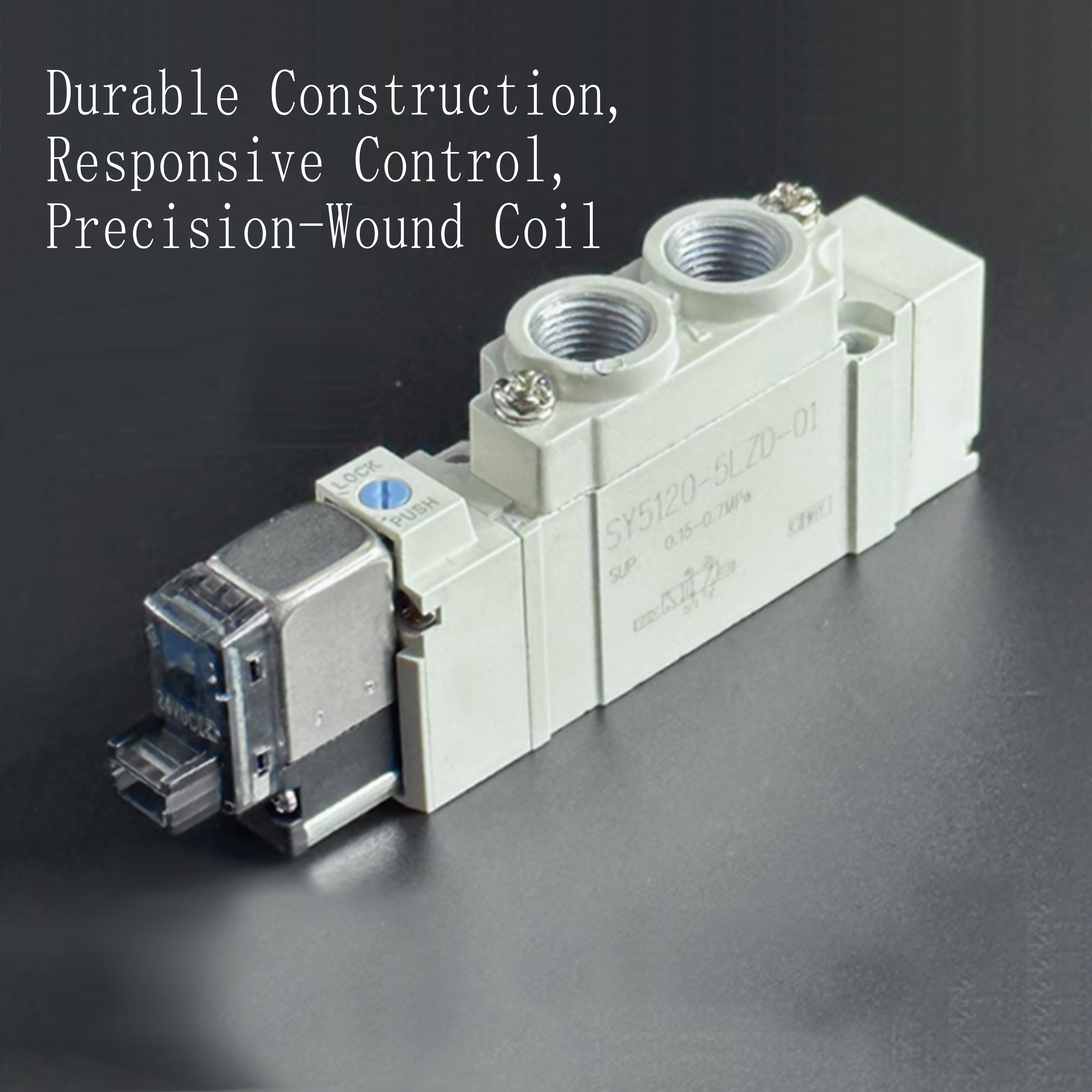

Modular integration: Multi-jaw synchronous control is achieved through SMC valve islands (such as the SY series), saving the cost of air pipe wiring.

Iii. Typical Application Scenarios

1.3C electronic manufacturing

Mobile phone assembly: Grasp the 0.3 mm-thick FPC flexible board and prevent deformation through the high rigidity of the built-in guide rail.

Chip packaging: In conjunction with the vision system, it achieves wafer picking and placing with an accuracy of ±0.01mm, meeting the cleanliness requirements of the semiconductor industry.

2. Automotive parts processing

Engine assembly: Grab a piston ring weighing 300g and achieve smooth grasping through variable throttling control.

Wiring harness treatment: Use POM grippers to prevent damage to the wiring harness caused by metal contact.

3. Food packaging

Drug sorting: Select the non-lubricated version (-Z73), which complies with FDA food-grade certification to avoid grease contamination.

Soft bag packaging: By adjusting the opening and closing speed (0.1m/s), it prevents the squeezing of fragile items.

Iv. Maintenance and Troubleshooting

1. Preventive maintenance

Lubrication cycle: Every 500 hours or 100,000 cycles, ISO VG32 lubricating oil is injected through an oil mist lubricator (such as AL series).

Seal inspection: Inspect the piston rod seal ring (model DSN-20) every quarter. If the wear is greater than 0.1mm, it needs to be replaced.

Guide rail cleaning: Wipe the surface of the guide rail with anhydrous ethanol every month to prevent the accumulation of metal debris.

2. Common Fault Handling

| Fault phenomenon | Possible reasons | Solution |

| Insufficient clamping force | Low air pressure/Aging of the piston seal | Check the air pressure/Replace the seals |

| The gripper shakes. | The throttle valve opening is too large/The guide rail is short of oil | Reduce the throttle valve/replenish the lubrication |

| Position detection failed | Magnetic switch installation offset/sensor failure | Recalibrate/replace the sensor |

V. Comparison of Competing Products and Selection Suggestions

| Model | Clamping torque (N · m) | Repeatability accuracy (mm) | Price range | Advantageous scenarios |

| MHC2-20D | 0.70 | ±0.01 | - | High precision, medium load |

| Festo ADN-20 | 0.55 | ±0.02 | - | Fast response (10ms) |

| Airtac MHF2-20 | 0.60 | ±0.015 | - | Economical and small-batch |

Selection suggestions:

Give priority to MHC2-20D: When high rigidity (double piston + guide rail structure), high precision (±0.01mm), and modular expansion are required.

Consider Festo ADN-20: If an extremely high response speed is required (such as high-speed sorting), but a 20% cost premium needs to be accepted.

Budget-sensitive scenarios: The Airtac MHF2-20 can be used as an alternative, but it should be noted that its repeatability accuracy and lifespan are relatively low.

Vi. Industry Standards and Compliance

Certification: Complies with the ISO 15552 pneumatic standard and is optional with the CE certification version (-CE).

Explosion-proof: When used in hazardous environments, explosion-proof solenoid valves (such as VEX series) should be used in conjunction.

Cleanliness: The cleanroom version (-Z73) complies with ISO level 4 standards, with particle release < 0.1mg/h.

Through a comprehensive assessment of the above dimensions, the MHC2-20D stands out in terms of precise grasping, modular integration, and environmental adaptability, making it particularly suitable for scenarios in automated production lines where precision and reliability are highly demanded. It is recommended to generate a 3D model through the official SMC selection tool (such as CAD selection software) for assembly verification based on the specific working conditions.

= = = = = = = = = = = = = = = = = = = = = = = = = = =

I am a distributor of pneumatic components, with first-hand supply. We guarantee brand new, original, and genuine products. With over ten years of experience in the pneumatic component industry, the spirit of contract is our lifeblood. Our product prices are very competitive, the delivery time is stable, and we have a large amount of stock and quasi-stock. Honesty, reliability, and win-win cooperation lead to a long-lasting relationship. I hope to have the opportunity to cooperate with you. Main brands: SMC, FESTO, AirTAC, CKD, Siemens PLC, etc.