if your pneumatic solenoid valve isn't running, several potential problems might be inflicting the trouble. right here’s a checklist to assist diagnose and cope with the hassle:

1. strength supply troubles

hassle: The solenoid coil is not receiving energy.

solution:

take a look at the voltage and current on the coil terminals to ensure it suits the valve specs.

inspect for unfastened connections, broken wires, or a blown fuse.

2. Coil Burnout

trouble: The solenoid coil has burned out due to overheating or extended energization.

answer:

check the coil resistance with a multimeter. If it reads "open" or "countless," replace the coil.

make certain the valve's responsibility cycle matches its operational requirements.

3. Mechanical Blockage

trouble: dirt, particles, or infection has obstructed the inner components of the valve.

solution:

Disassemble the valve (following the producer's commands) and easy it very well.

install a proper air clear out within the machine to prevent future infection.

4. Air deliver issues

problem: insufficient or no air strain is attaining the valve.

solution:

check the air supply for correct stress and glide.

check out for leaks inside the air traces or blocked filters.

5. Valve Sticking

hassle: The internal shifting components, consisting of the plunger or spool, are caught due to lack of lubrication or corrosion.

answer:

clean and lubricate the valve additives as endorsed via the manufacturer.

replace any corroded or worn parts.

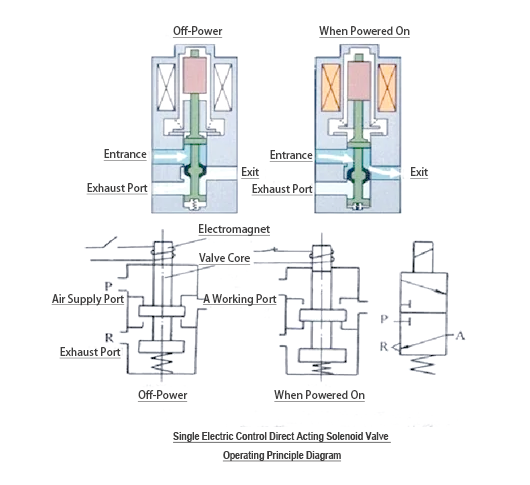

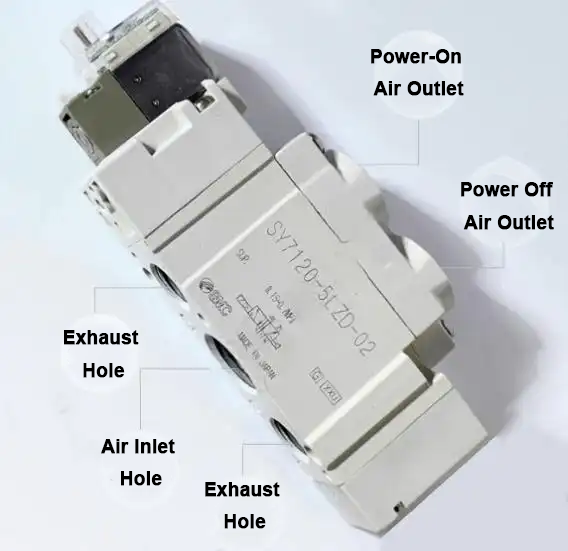

6. incorrect set up

trouble: The valve is mounted incorrectly, including reversed connections or mistaken orientation.

solution:

verify the installation towards the user manual, ensuring the inlet, outlet, and exhaust ports are efficaciously linked.

verify that the valve is mounted inside the right function.

7. Overpressure or Undersized Valve

trouble: The valve is subjected to air strain past its layout limits or is undersized for the software.

answer:

take a look at the operating pressure towards the valve's specifications.

Use a valve with the suitable length and stress score.

8. electric signal troubles

trouble: The control machine isn't always sending the appropriate sign to the solenoid.

answer:

take a look at the manage circuit, consisting of switches, relays, and controllers.

make certain the signal timing suits the valve's working requirements.

9. put on and Tear

hassle: The valve components have degraded over time because of common use or harsh situations.

answer:

look into the seals, diaphragms, and different wear-prone components. update them if important.

recollect upgrading to a greater long lasting valve for traumatic packages.

10. Temperature Extremes

hassle: The valve is uncovered to temperatures beyond its running variety, causing malfunction or cloth degradation.

solution:

Relocate the valve to a temperature-managed environment or insulate it.

Use a valve rated for high temperature conditions.

If none of those solutions remedy the issue, seek advice from the producer or a expert technician for in addition diagnosis. proper renovation and everyday inspections can help prevent many of those issues.