Specification: | |||||||||||||

Bore size: | 6 | 10 | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | |

Acting type: | Double Acting | ||||||||||||

Fluid: | Air(to be filtered by a 40μm filter element) | ||||||||||||

Operating Pressure: | 0.2~0.7MPa | 0.15~1.0MPa | |||||||||||

Proof pressure: | 1.2MPa(175psi) | 1.5MPa(215psi) | |||||||||||

Temperature(℃): | -20~70 | ||||||||||||

Speed rang (mm/s): | 50~500 | 30~500 | 50~400 | ||||||||||

Stroke tolerance: | (0~+1.0) | ||||||||||||

Cushion Type: | Burmper | ||||||||||||

Non-rotating Tolerance: | TCL | _ | ±0.08° | ±0.07° | ±0.06° | ±0.05° | |||||||

TCM | ±0.1° | ±0.10° | ±0.09° | ±0.08° | ±0.06° | ||||||||

Port Size: | M3X0.5 | M5X0.8 | PT1/8 | PT1/4 | PT3/8 | ||||||||

Enhanced Stability. Strong Load Support. Precision Movement.

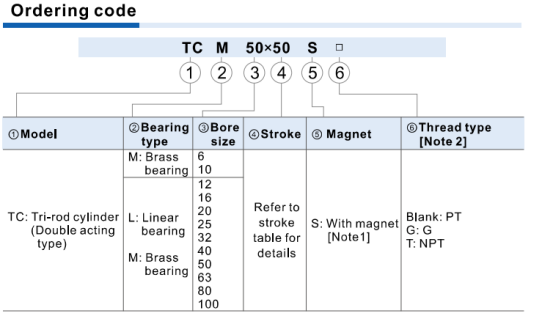

The TCM Series Tri-Rod Pneumatic Cylinder follows the JIS standard and features an integrated drive and guide design. It is engineered for applications requiring high anti-rotation performance, radial load resistance, and compact installation. You can choose between linear ball bearings or bronze sliding bearings, depending on your application's needs.

JIS Standard Compliant

Built with international JIS specifications for easy replacement and global compatibility.

Tri-Rod Anti-Rotation Design

Uses two precision guide rods made of special bearing steel with either linear ball bearings or bronze bearings to prevent shaft rotation, ensuring high accuracy and durability.

Integrated Drive and Guide in One Body

The actuator and guide are combined in a single barrel. This reduces the space needed and eliminates extra components. Multiple air inlet ports allow flexible piping and easy installation.

High-Precision Mounting Options

Orientation holes on the bottom, back, and mounting plate allow accurate alignment for custom installations. These are marked with ΦPA and XX-position orifices for exact placement.

Sensor Slot Compatibility

Equipped with four sensor slots to support magnetic switch installation and stroke detection.

Multi-Mount Flexibility

The body’s design includes multiple mounting surfaces, making it easy to install in tight or variable positions.

Application Fields

The TCM Series Tri-rod Pneumatic Cylinder are widely used in:

Precision pressing or pushing in small automation setups

Equipment with strong lateral or torque movement

Vertical lifting mechanisms requiring low friction

Compact assembly lines with limited space

Packaging, testing, or sorting machines

JoosungAuto is a professional pneumatic cylinder manufacturer based in China. We offer a full range of automation components, including TCM/TCL Series Tri-rod Pneumatic Cylinder, CU/CDU compact cylinders, and 4V series solenoid valves.

With strong OEM support, fast production, and flexible customization, JoosungAuto provides stable, affordable, and globally compatible pneumatic solutions.

Looking for a compact and durable pneumatic cylinder with enhanced precision and stability? The TCM Tri-Rod Cylinder with brass bearing is your trusted choice for advanced automation systems.

Visit us:

www.joosungauto.com

www.autojoosung.com

Contact Us:

Email: bob@joosungauto.com

WhatsApp: +86 13780101113

#TCM #TriRodCylinder #BrassBearingCylinder #PneumaticCylinder #AutomationCylinder #JoosungAuto #OEMPneumatics #AirCylinders #CompactCylinder

Series Model | Available Models |

TCM6 Series | TCM6-5S, TCM6-10S, TCM6-15S, TCM6-20S |

TCM10Series | TCM10-5S, TCM10-10S, TCM10-15S, TCM10-20S, TCM10-25S, TCM10-30S |

TCM12Series | TCM12-10S, TCM12-20S, TCM12-25S, TCM12-30S, TCM12-40S, TCM12-50S, TCM12-60S, TCM12-70S, TCM12-75S, TCM12-80S, TCM12-90S, TCM12-100S, TCM12-125S, TCM12-150S |

TCM16 Series | TCM16-10S, TCM16-20S, TCM16-25S, TCM16-30S, TCM16-40S, TCM16-50S, TCM16-60S, TCM16-70S, TCM16-75S, TCM16-80S, TCM16-90S, TCM16-100S, TCM16-125S, TCM16-150S, TCM16-175S, TCM16-200S |

TCM20 Series | TCM20-20S, TCM20-25S, TCM20-30S, TCM20-40S, TCM20-50S, TCM20-60S, TCM20-70S, TCM20-75S, TCM20-80S, TCM20-90S, TCM20-100S, TCM20-125S, TCM20-150S, TCM20-175S, TCM20-200S, TCM20-225S, TCM20-250S |

TCM25 Series | TCM25-20S, TCM25-25S, TCM25-30S, TCM25-40S, TCM25-50S, TCM25-60S, TCM25-70S, TCM25-75S, TCM25-80S, TCM25-90S, TCM25-100S, TCM25-125S, TCM25-150S, TCM25-175S, TCM25-200S, TCM25-225S, TCM25-250S |

TCM32 Series | TCM32-25S, TCM32-30S, TCM32-40S, TCM32-50S, TCM32-60S, TCM32-70S, TCM32-75S, TCM32-80S, TCM32-90S, TCM32-100S, TCM32-125S, TCM32-150S, TCM32-175S, TCM32-200S, TCM32-225S, TCM32-250S |

TCM40Series | TCM40-25S, TCM40-30S, TCM40-40S, TCM40-50S, TCM40-60S, TCM40-70S, TCM40-75S, TCM40-80S, TCM40-90S, TCM40-100S, TCM40-125S, TCM40-150S, TCM40-175S, TCM40-200S, TCM40-225S, TCM40-250S |

TCM50Series | TCM50-25S, TCM50-30S, TCM50-40S, TCM50-50S, TCM50-60S, TCM50-70S, TCM50-75S, TCM50-80S, TCM50-90S, TCM50-100S, TCM50-125S, TCM50-150S, TCM50-175S, TCM50-200S, TCM50-225S, TCM50-250S |

TCM63Series | TCM63-25S, TCM63-30S, TCM63-40S, TCM63-50S, TCM63-60S, TCM63-70S, TCM63-75S, TCM63-80S, TCM63-90S, TCM63-100S, TCM63-125S, TCM63-150S, TCM63-175S, TCM63-200S, TCM63-225S, TCM63-250S |

TCM80Series | TCM80-25S, TCM80-30S, TCM80-40S, TCM80-50S, TCM80-60S, TCM80-70S, TCM80-75S, TCM80-80S, TCM80-90S, TCM80-100S, TCM80-125S, TCM80-150S, TCM80-175S, TCM80-200S, TCM80-225S, TCM80-250S |

TCM100Series | TCM100-25S, TCM100-30S, TCM100-40S, TCM100-50S, TCM100-60S, TCM100-70S, TCM100-75S, TCM100-80S, TCM100-90S, TCM100-100S, TCM100-125S, TCM100-150S, TCM100-175S, TCM100-200S, TCM100-225S, TCM100-250S |