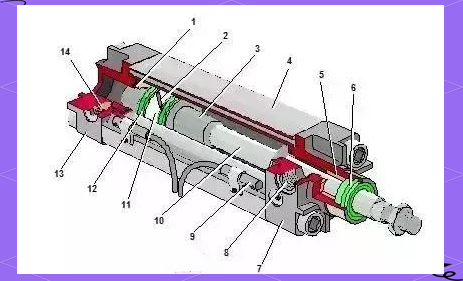

An electromagnetic valve is a device that uses electromagnetic force to control the flow of fluids or gases. It is mainly composed of the valve body, valve core, electromagnetic coil, and spring etc.

When the electromagnetic coil is energized, a magnetic field is generated, causing the valve core to be attracted or repelled by magnetic force, thereby controlling the flow direction and speed of the medium.

Solenoid valves are widely used in fields such as automatic control systems, industrial production, petrochemicals, etc. They have the advantages of simple structure, fast response speed, and high reliability.

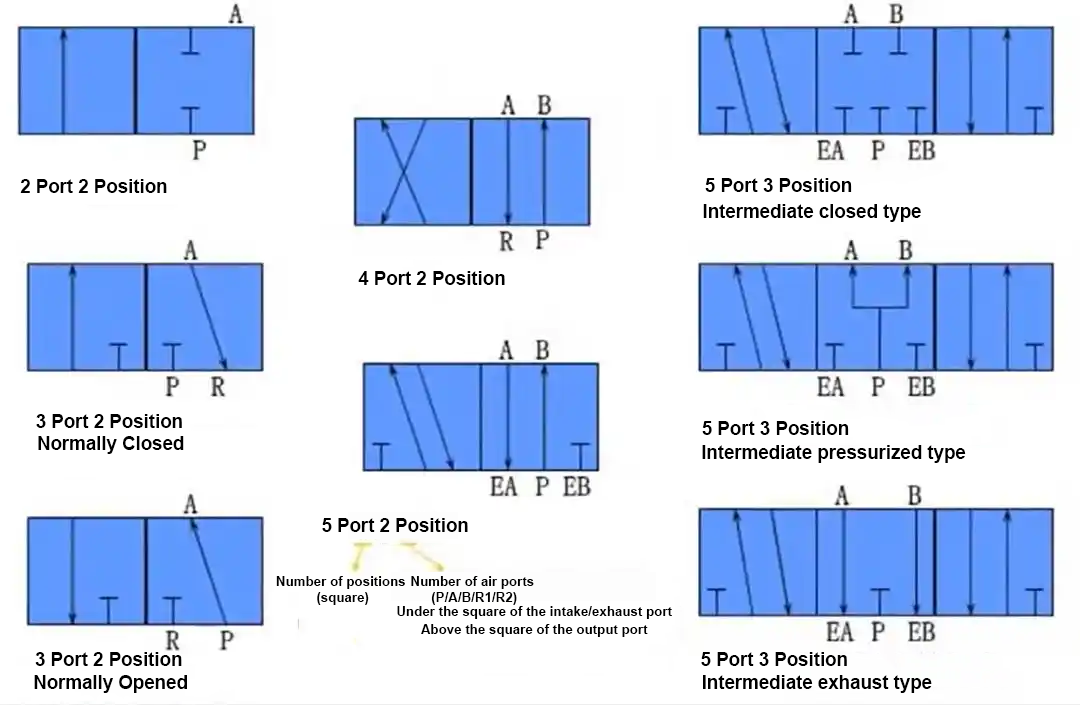

Pneumatic solenoid valves have many ways and positions according to their functions and requirements.

There are two-position two-way, two-position three-way, two-position five-way, two-position four-way and solenoid valves. (Two-position five-way and two-position four-way are further divided into single electronic control and dual electronic control types.)

Of course, the simplest and most commonly used ones are the two-position three-way solenoid valve and the two-position five-way solenoid valve. The three-position five-way solenoid valve should be used only when the cylinder (actuator) needs to stop in the middle.

"Through" and "position" are important concepts of pneumatic reversing solenoid valves.

Different "on" and "position" constitute different types of pneumatic reversing solenoid valves.

The so-called "two-position valve" and "three-position valve" usually refer to the fact that the valve core of the directional control valve has two or three different working positions.

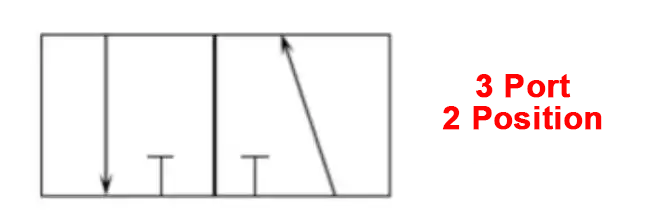

The so-called "two-way valve", "three-way valve" and "four-way valve" refer to the two, three or four interfaces on the valve body of the directional control valve that are not interconnected but can be connected to different oil or gas pipes in the system. Different oil channels/gas lines can only communicate with the "several positions" in front through the opening and closing of the valve port when the valve core moves. You need to see how many working states this valve has to say how many positions it is. If there are symbols for pneumatic components, it will be easier to understand. On the symbol, the number of squares (with arrows or T-lines inside) representing the valve body is the number of positions.

The "jitong" in the latter part represents the number of points on one of the squares (the points that intersect with the arrow line and the T line), which is the jitong.

The meanings of graphic symbols are generally as follows:

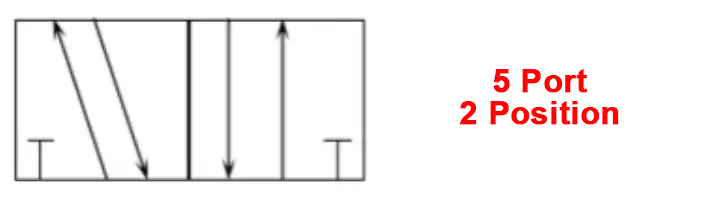

(1) Use boxes to indicate the working position of the valve. The number of boxes indicates the number of "positions".

(2) The arrows within the box indicate that the oil circuit is connected, but the direction of the arrows does not necessarily represent the actual direction of the liquid flow.

(3) The symbols "┻" or "┳" in the box indicate that the passage is blocked;

(4) The number of interfaces connected outside the box indicates how many are "connected".

(5) Generally, the oil inlet/air inlet where the valve is connected to the system's oil supply line or air is represented by the letter p. The return oil/return gas port where the valve is connected to the system's return oil line/gas line is represented by t (sometimes o). The oil port/air port where the valve is connected to the actuator is indicated by a, b, etc. Sometimes it is used on graphic symbols to represent the oil leakage port.

(6) Directional control valves all have two or more working positions, one of which is the normal position, that is, the position where the valve core is located when it is not subjected to operating force.

The middle position in the graphic symbol is the normal position of the three-position valve. The two-position valve that uses spring return takes the state of the passage within the box close to the spring as its normal position.

When drawing the system diagram, the oil circuit/gas circuit should generally be connected to the normal position of the directional control valve. The number of positions refers to the number of working states of the valve. The number of working states is the number of positions. The number of digits in the corresponding graphic symbol square is the same.

"---Position?" refers to the number of points in one of the squares—corresponding graphic symbols: arrow line and T. The two ends of the arrow line are two points, and T represents one point.

The direction of the arrow indicates the flow direction of the gas in the gas path. A bidirectional arrow suggests that the gas can flow in both directions.

T indicates that this road is blocked.

Two-position three-way (1 intake, 1 exhaust, 1 exhaust)

Two-position five-way (1 intake, 2 exhaust, 2 exhaust)

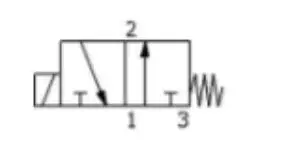

Generally, the air inlet is represented by "P", the exhaust port by "R" and "S" (on the same side as the air inlet), and the air ports connected to the actuator by "A" and "B".

Generally, solenoid valves have two or more working positions. One of them is the normal position.

The normal position refers to the position of the valve core when it is not subjected to electromagnetic force (the box near the end of the spring is shown in the figure).

So:

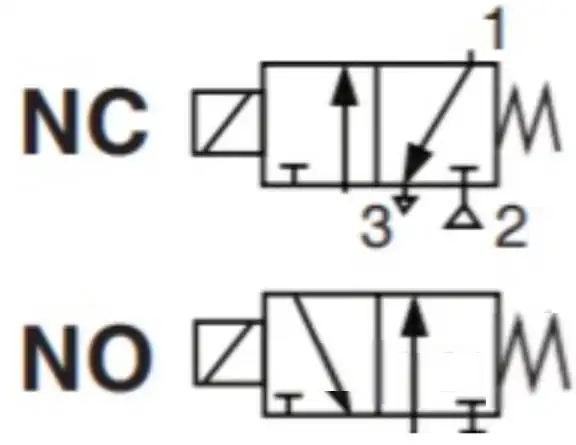

The following figure shows NC as the normally closed solenoid valve Q(when not powered on, the gas supply is cut off).

In the following figure, NO represents the normally open solenoid valve Q(gas is flowing when not powered on).

When the solenoid valve needs to be started for a long time and the continuous opening time is much longer than the closing time, it is advisable to choose a normally open solenoid valve.

When the solenoid valve frequently switches between opening and closing, or the opening time is short, or the time difference between opening and closing is not significant, a normally closed solenoid valve should be selected

The symbol in the following figure indicates that the solenoid valve is direct-acting

The symbol in the following figure indicates that the solenoid valve is a pilot-operated type

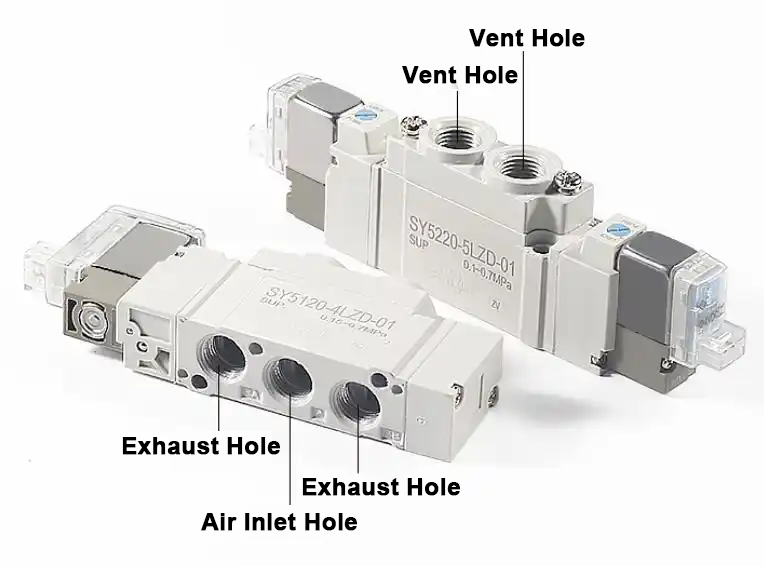

Five-way means there are five channels for ventilation

One of them is connected to the gas source.

The two are connected to the air inlet and outlet of the external air chamber of the double-acting cylinder.

The two air inlets and outlets are connected to the internal air chamber.

The specific working principle can be referred to that of the double-acting pneumatic actuator. In terms of the air path (or liquid path) :

The two-position three-way solenoid valve has one air inlet (for connecting to the air source), one air outlet (for providing the air source to the target equipment), and one air outlet (usually equipped with a muffler; if noise is not a concern, it can also be omitted).

The two-position five-way solenoid valve has one air inlet hole (connected to the air source for intake), one forward action air outlet hole and one reverse action air outlet hole (respectively providing one forward and one reverse action air source for the target equipment), one forward action exhaust hole and one reverse action exhaust hole (with a muffler installed).

For small automatic control equipment, industrial rubber air pipes with a diameter of 8 to 12 are generally selected for the air pipes.

For small automatic control equipment, industrial rubber air pipes with a diameter of 8 to 12 are generally selected for the air pipes.

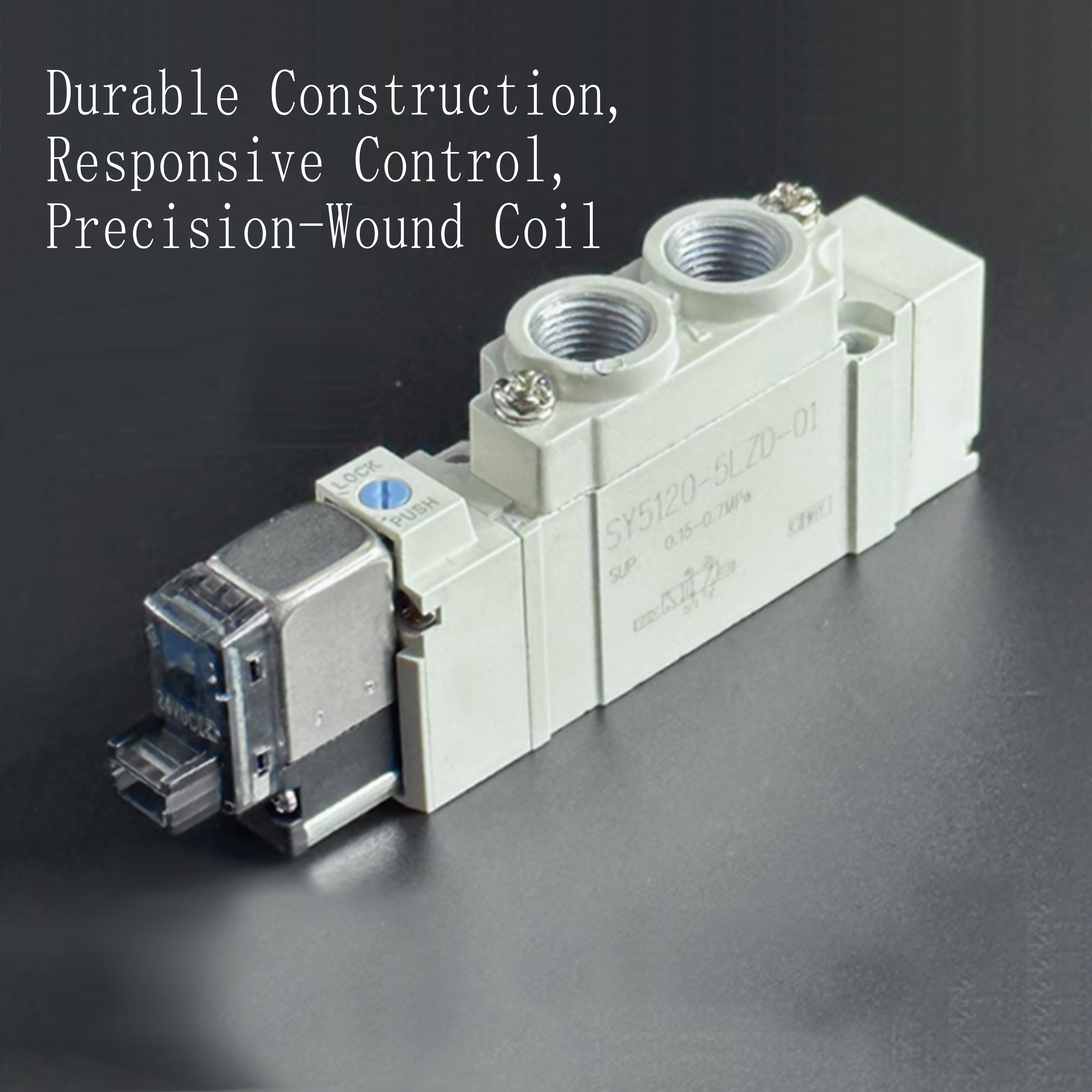

Electrically speaking, two-position three-way solenoid valves are generally single-controlled (i.e., single-coil), while two-position five-way solenoid valves are typically double-controlled (i.e., double-coil).

The coil voltage levels are generally DC24V, AC220V, etc.

Two-position three-way solenoid valves are divided into two types: normally closed and normally open.

The normally closed type refers to the situation where the air path is disconnected when the coil is not energized.

The normally open type refers to the situation where the airway is open when the coil is not energized.

Operating principle of two-position five-way double electrically controlled solenoid valve:

When the forward action coil is energized, the forward action airway is connected (there is air at the forward action air outlet). Even if the forward action coil is de-energized, the forward action airway remains connected and will remain so until the reverse action coil is energized.

When the reverse action coil is energized, the reverse action airway is connected (there is air in the air hole of the reverse action coil). Even after the reverse action coil is de-energized, the reverse action airway remains connected and will remain so until the forward action coil is energized. This is equivalent to "self-locking".

Based on this characteristic of the two-position five-way double electric control solenoid valve, when designing the electromechanical control circuit or programming the PLC, it is only necessary to let the solenoid valve coil operate for 1 to 2 seconds. This can protect the solenoid valve coil from being easily damaged.