within the equipment enterprise, the Pneumatic cylinder, as an essential govt detail, is widely used in diverse automation system and manufacturing traces. however, because of various motives, the cylinder could have diverse disasters in the course of use, affecting the normal operation of the gadget. most effective by information the commonplace faults and answers of the cylinder can we higher maintain and use the cylinder.

within the equipment enterprise, the Pneumatic cylinder, as an essential govt detail, is widely used in diverse automation system and manufacturing traces. however, because of various motives, the cylinder could have diverse disasters in the course of use, affecting the normal operation of the gadget. most effective by information the commonplace faults and answers of the cylinder can we higher maintain and use the cylinder.

①, the cylinder leakage

Cylinder leakage is one of the not unusual screw ups, generally resulting from cracks or damage to the cylinder wall or cylinder gasket. Air leakage will lead to inadequate cylinder stress, affecting the regular operation of the cylinder.

The solution:

1. replace the cylinder wall or gasket. when changing the gasket, it's far vital to pay attention to the material and size of the gasket to fulfill the standard, and make sure that the sealing floor is clean and with out scratches while installing.

2. while changing the cylinder wall, the cylinder desires to be boring or changed.

②. Piston wear

The piston is an essential a part of the cylinder, and long-term use can also cause piston wear, affecting the compression capability and running balance of the cylinder.

The solution:

1. update the worn piston. when replacing the piston, it's miles vital to pay attention to the dimensions and fabric of the piston to satisfy the same old, and ensure the coaxial degree of the piston and the cylinder when putting in.

2. check the wear and tear of the piston often and replace the worn piston in time.

③, the cylinder is not working normally

The extraordinary operation of the cylinder can be resulting from a spread of motives, along with moist air inside the cold joint, liquid degree within the piston rod, the joint clamping isn't always robust, and the air outlet is blocked.

The solution:

1. Disassemble the cylinder for preservation, smooth it and reinstall it. during the set up, ensure that the additives are effectively hooked up and securely connected, and make sure the cleanliness of the cylinder.

2. make stronger the day by day preservation and maintenance of the cylinder, often take a look at the operating popularity of every component, and well timed discover and solve capability faults.

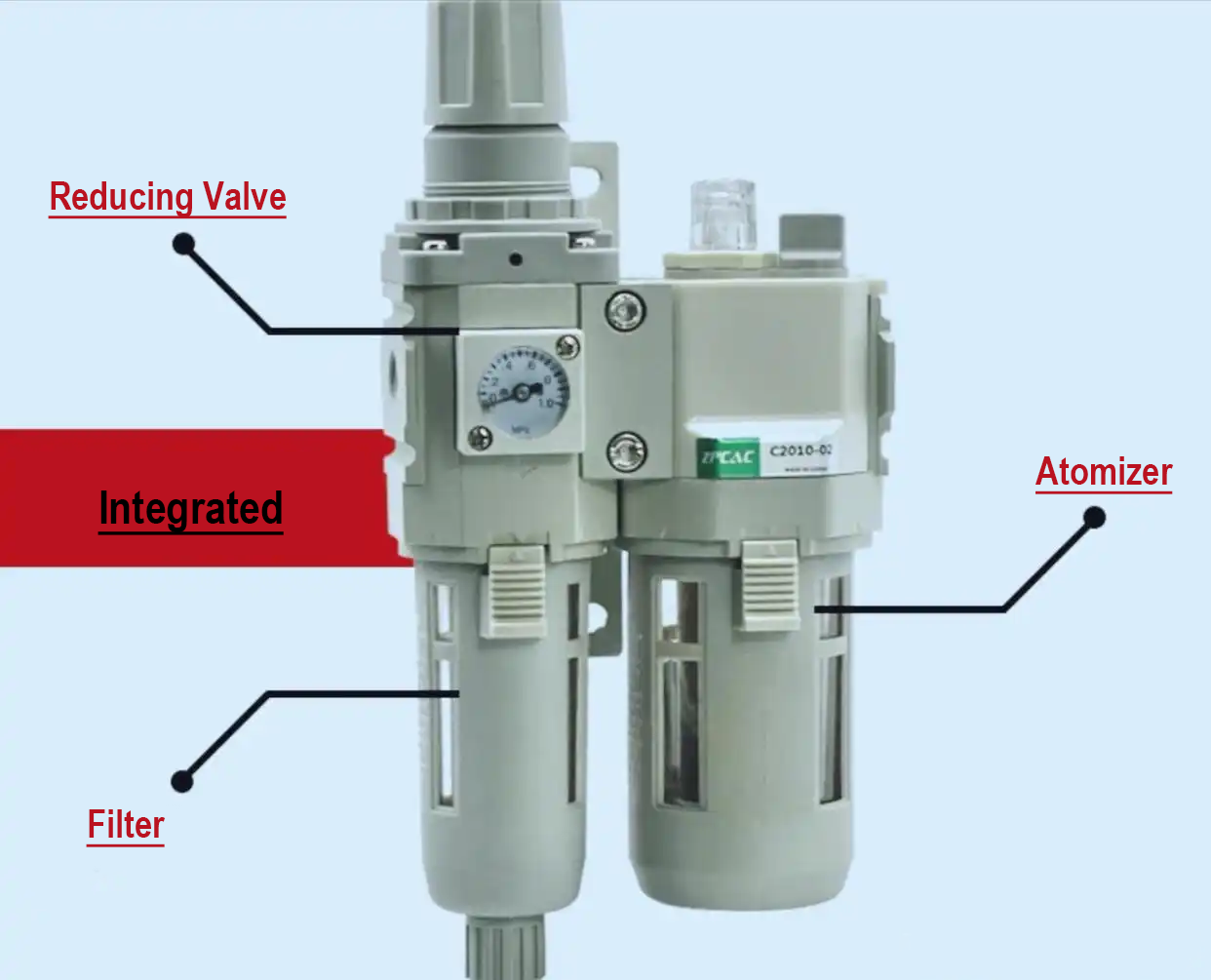

④, pneumatic actuator failure

Pneumatic actuator fault is also one of the common faults, consisting of internal and external leakage, inadequate output pressure and choppy action. this can be because of eccentric piston rod set up, inadequate supply of lubricating oil, put on or damage to seals and sealing earrings, and so on.

The solution:

1. Readjust the center of the piston rod to make certain its coaxiality with the cylinder.

2. often take a look at whether or not the oil mist works reliably to make sure that the actuator is well lubricated.

3. update the worn or broken seal ring and seal ring in time.

4. get rid of impurities from the cylinder.

5. update the bruised piston rod.

6. take a look at and maintain the pneumatic actuator often to find out and remedy capacity faults in time.

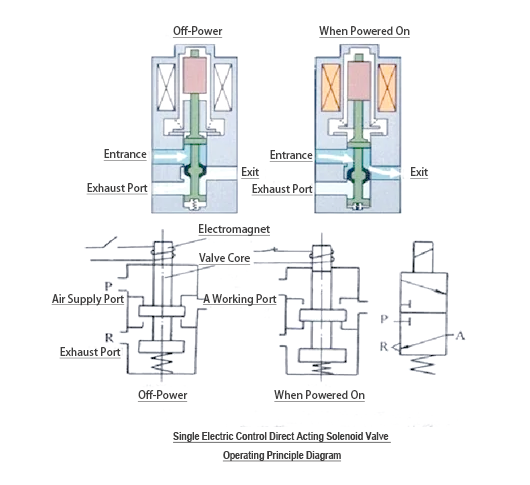

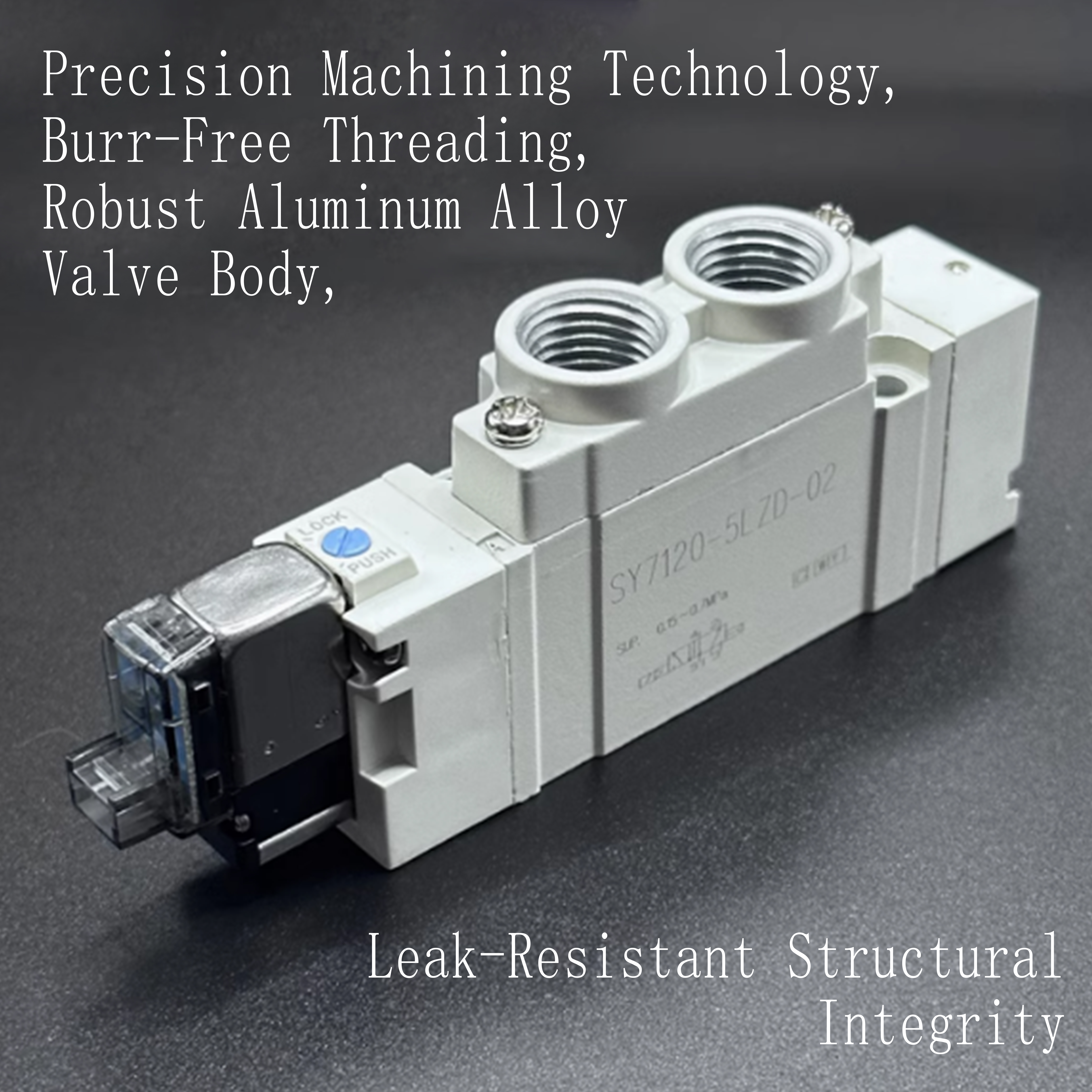

⑤, the solenoid valve coil is burned out or the valve center is caught

The solenoid valve is an vital component to govern the movement of the cylinder. If the solenoid valve coil is burned out or the valve core is caught, the cylinder will not paintings.

The solution:

replace the solenoid coil or clean the spool. when installing the solenoid valve, ensure that it's far securely connected to the cylinder and that cables are effectively and reliably related. on the same time, it is important to apply certified additives to reinforce the renovation and renovation of components.