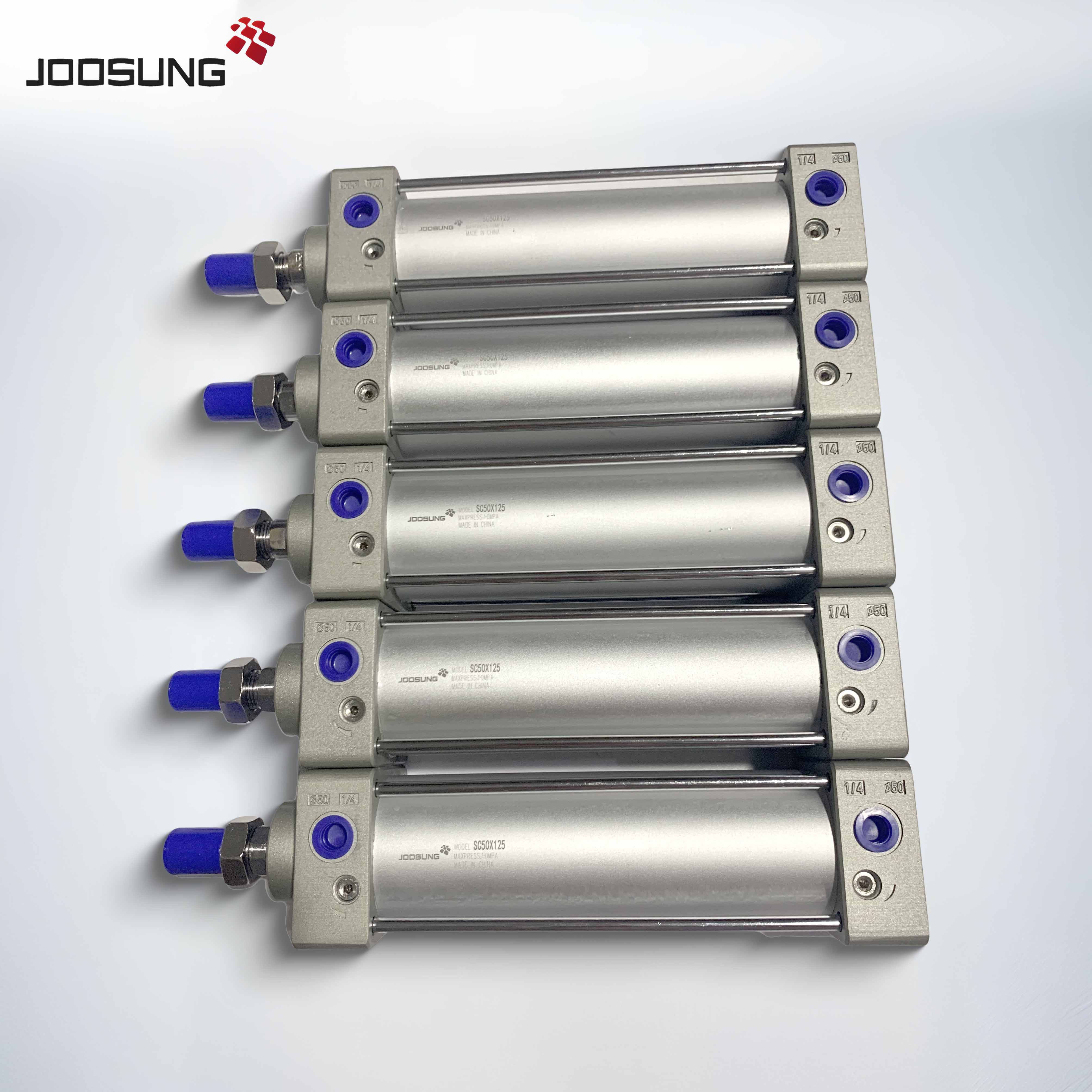

If a pneumatic cylinder is poorly sealed, it is able to cause air leakage, strain loss, and decreased overall performance. below are the commonplace causes, signs, and solutions for terrible sealing in a pneumatic cylinder.

reasons of bad Sealing in a Pneumatic Cylinder

1. Worn or broken Seals

through the years, seals degrade because of put on, publicity to contaminants, or wrong lubrication.

commonplace failure points: piston seals, rod seals, and end cap seals.

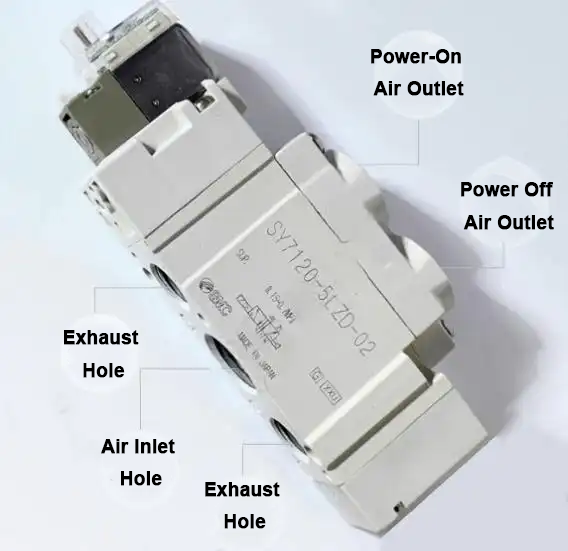

2. incorrect Seal set up

If seals are not set up properly, they'll now not in shape tightly, leading to air leakage.

mistaken alignment can reason choppy wear or damage in the course of meeting.

3. bad Seal cloth desire

some seals might not be appropriate for high strain, high temperature, or competitive chemical compounds inside the air deliver.

example: Nitrile (NBR) seals are not perfect for excessive temperatures; Viton or PTFE can be wished.

4. Contaminants within the gadget

dirt, dirt, or moisture within the air deliver can motive seal degradation and leaks.

loss of proper filtration within the pneumatic machine lets in contaminants to damage seals.

5. excessive Friction or Misalignment

Misaligned rods or facet hundreds can placed pressure on seals, causing untimely put on.

loss of proper lubrication will increase friction, leading to quicker seal degradation.

6. Overpressure or immoderate Stroke velocity

If the cylinder operates beyond its pressure score, seals might also get broken or blow out.

high-pace moves without proper cushioning can motive shock masses on seals.

signs of Poorly Sealed Pneumatic Cylinders

✅ Air Leaks – Hissing sound close to the rod, piston, or end caps.

✅ loss of force – Cylinder struggles to increase/retract well.

✅ slow or Erratic movement – Cylinder moves inconsistently or stalls.

✅ excessive Air consumption – Compressor works harder to keep pressure.

✅ Oil or Air Leakage on the Rod – seen symptoms of leaks at the rod or quit caps.

solutions for negative Sealing in a Pneumatic Cylinder

1. investigate and update Seals

✔️ check seals for wear, cracks, or damage and replace them if wanted.

✔️ Use OEM-advocated seals for excellent fit and sturdiness.

2. make sure right set up

✔️ make sure seals are installed efficiently and flippantly.

✔️ Use seal lubricant all through installation to save you harm.

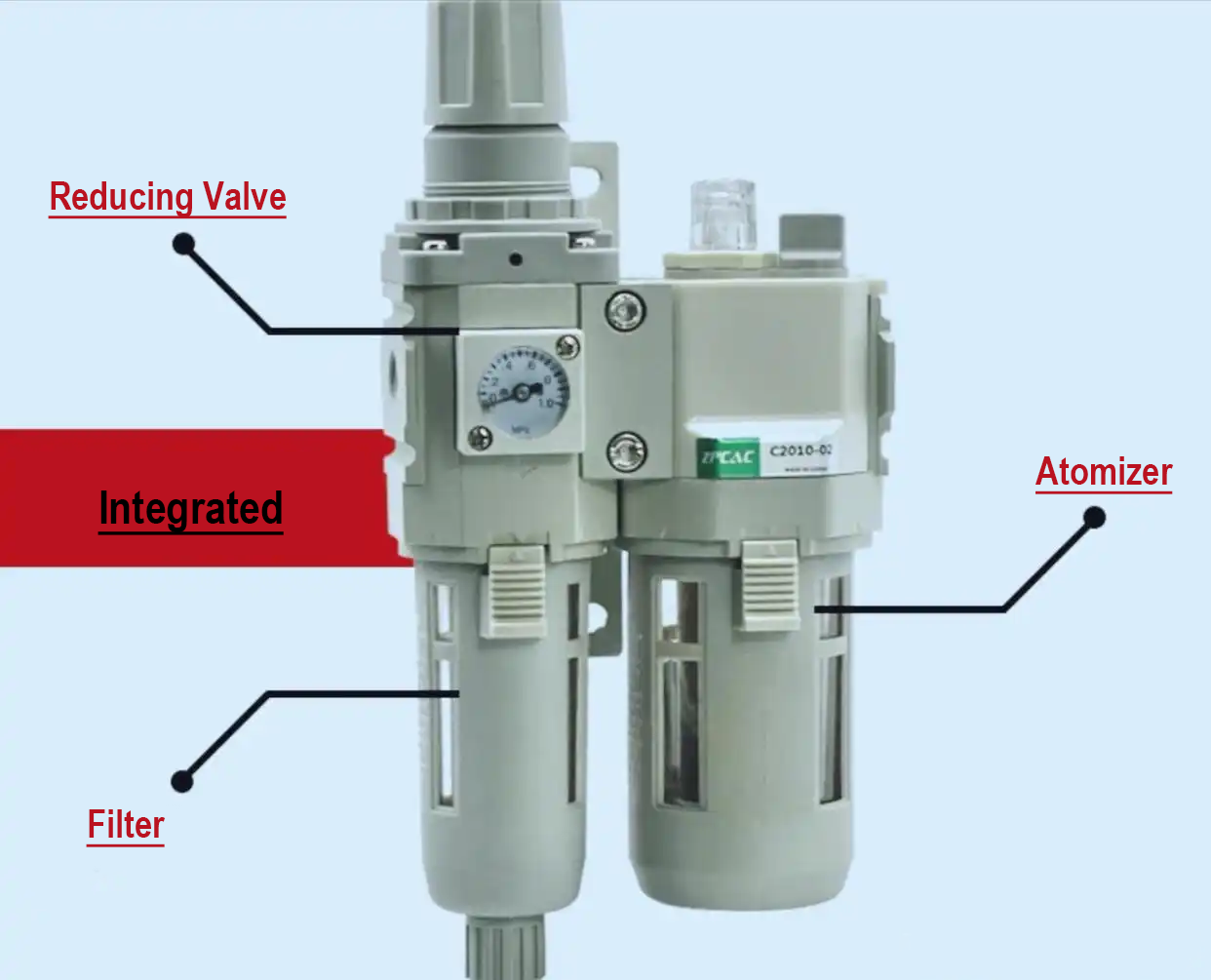

3. enhance Air pleasant

✔️ installation air filters and moisture traps to save you contaminants from destructive seals.

✔️ regularly test and replace filters to hold easy air deliver.

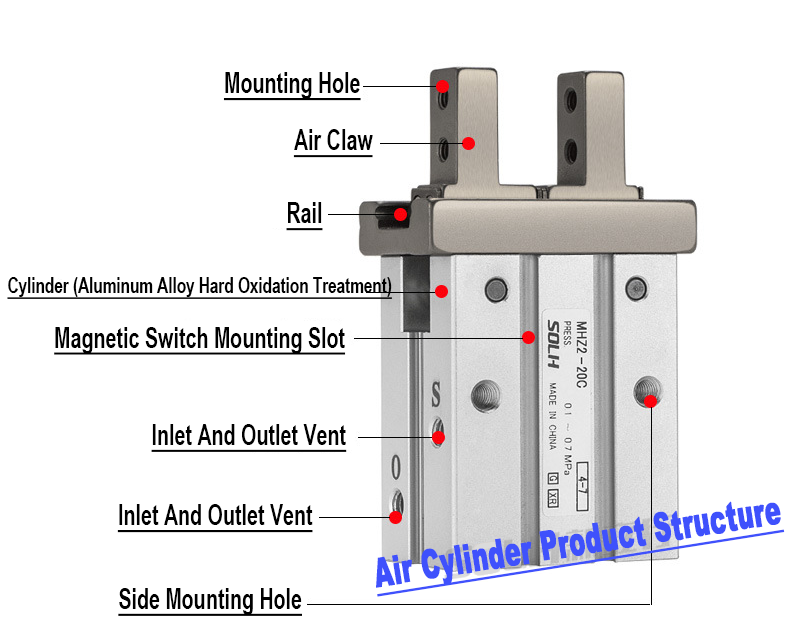

4. take a look at for Cylinder Misalignment

✔️ Align the cylinder nicely to reduce side hundreds on the piston rod.

✔️ ensure the mounting and rod connection are well focused.

5. practice right Lubrication

✔️ Use recommended pneumatic oil to save you friction and seal put on.

✔️ If the use of non-lubricated air, make sure seals are designed for dry operation.

6. alter running conditions

✔️ keep air pressure inside the cylinder's rated range.

✔️ If using excessive speeds, set up cushioning or surprise absorbers to shield seals.

Preventive maintenance tips

🔧 everyday Inspections – take a look at for air leaks, worn seals, and cylinder alignment.

🔧 Use smooth, Dry Air – install filters, dryers, and regulators to cast off moisture and contaminants.

🔧 right Lubrication – hold right oiling to extend seal existence.

🔧 display Cylinder speed and strain – avoid exceeding layout limits.

could you like assist selecting the right seals to your application? 😊