when running with double-appearing pneumatic cylinders, it is essential to comply with protection issues to prevent accidents, equipment harm, and make certain smooth operation. right here are the key safety factors:

1. stress and Air supply safety

ensure regulated air pressure inside the cylinder's rated limits to avoid overloading.

Use a clear out-regulator-lubricator (FRL) unit to preserve smooth, dry, and lubricated air.

install stress remedy valves to prevent excessive stress buildup.

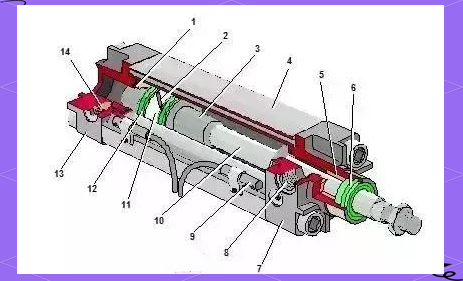

2. secure Mounting and Alignment

properly align the cylinder with the load to avoid aspect loading, which could reason wear or failure.

Use comfortable mounting brackets to prevent motion or vibrations that may loosen connections.

make certain the piston rod is parallel to the burden movement.

3. motion control & Cushioning

make use of float manipulate valves to modify speed and save you excessive effect.

Use cushioning mechanisms to soak up impact forces at the stop of the stroke.

keep away from surprising begins/stops through regularly increasing air stress at some point of preliminary operation.

4. Pinch and crush hazards

keep palms, gear, and garb faraway from the moving elements.

Use protection guards or boundaries to prevent accidental contact.

in reality mark dangerous zones around the cylinder.

5. Emergency stop and Lockout

deploy emergency stop controls to speedy shut off the air supply if wanted.

Use a lockout/tagout (LOTO) machine in the course of upkeep to prevent unintended activation.

make sure all stored pressure is absolutely launched before servicing the gadget.

6. proper Lubrication and preservation

often check out seals, hoses, and connections for leaks or damage.

Use well matched lubricants to save you cylinder malfunction.

hold the cylinder and surrounding area smooth to keep away from infection.

7. Load capacity and Stroke restrict

Do now not exceed the weight potential unique with the aid of the manufacturer.

make sure the stroke duration is within the cylinder’s mechanical limits to save you harm.

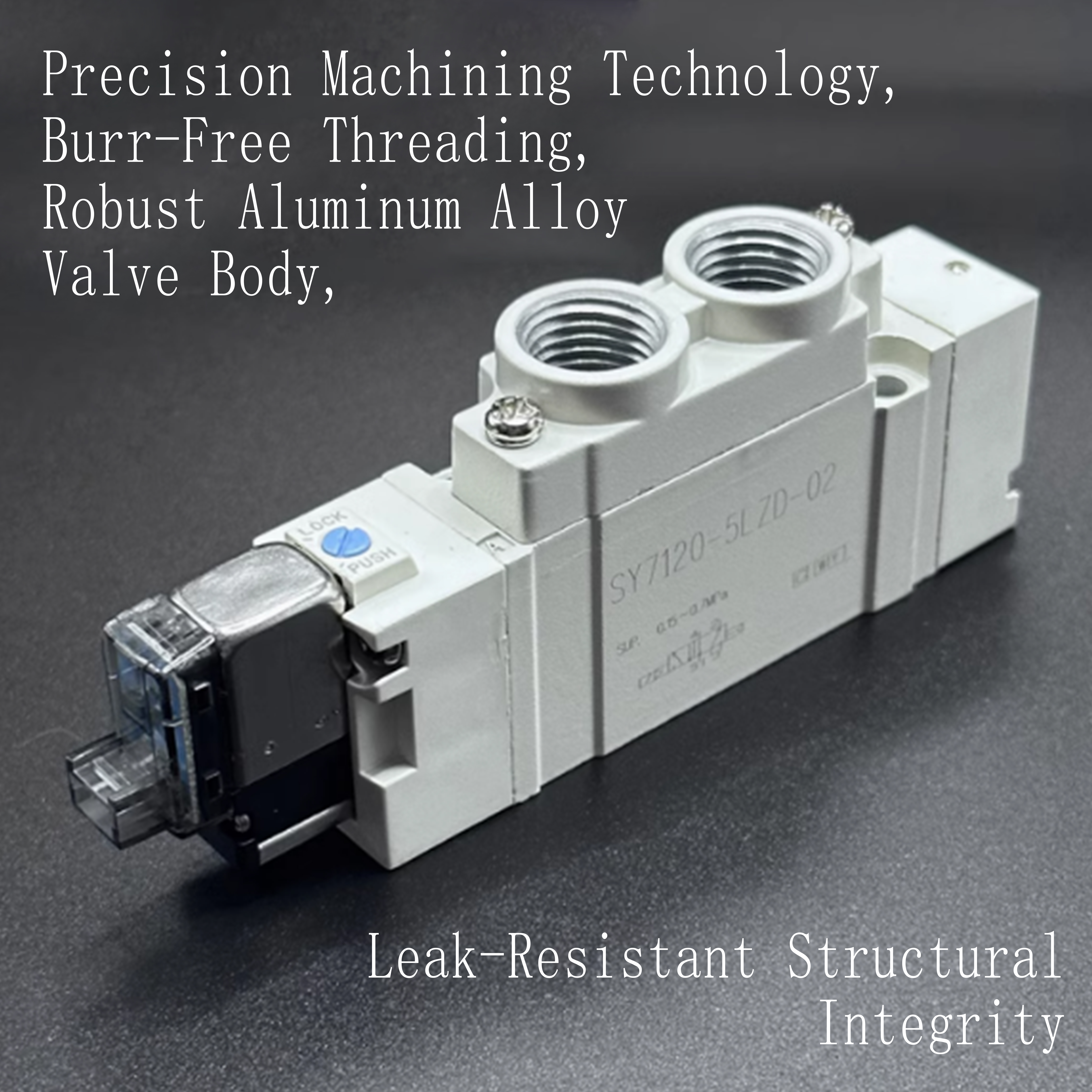

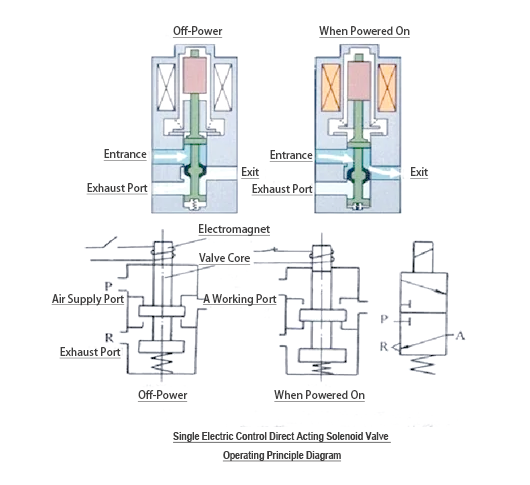

8. electrical and Pneumatic Connections

secure tubing and fittings to prevent air leaks and pressure loss.

maintain electric solenoids and sensors in proper working situation.

ensure right isolation among electrical additives and compressed air.

9. Environmental concerns

keep away from exposure to severe temperatures, corrosive materials, or excessive moisture.

Use corrosion-resistant materials if operating in harsh situations.

shield against dust or particles which can clog the pneumatic machine.

with the aid of following those safety precautions, you may make certain safe, efficient, and long-lasting operation of double-acting pneumatic cylinders.