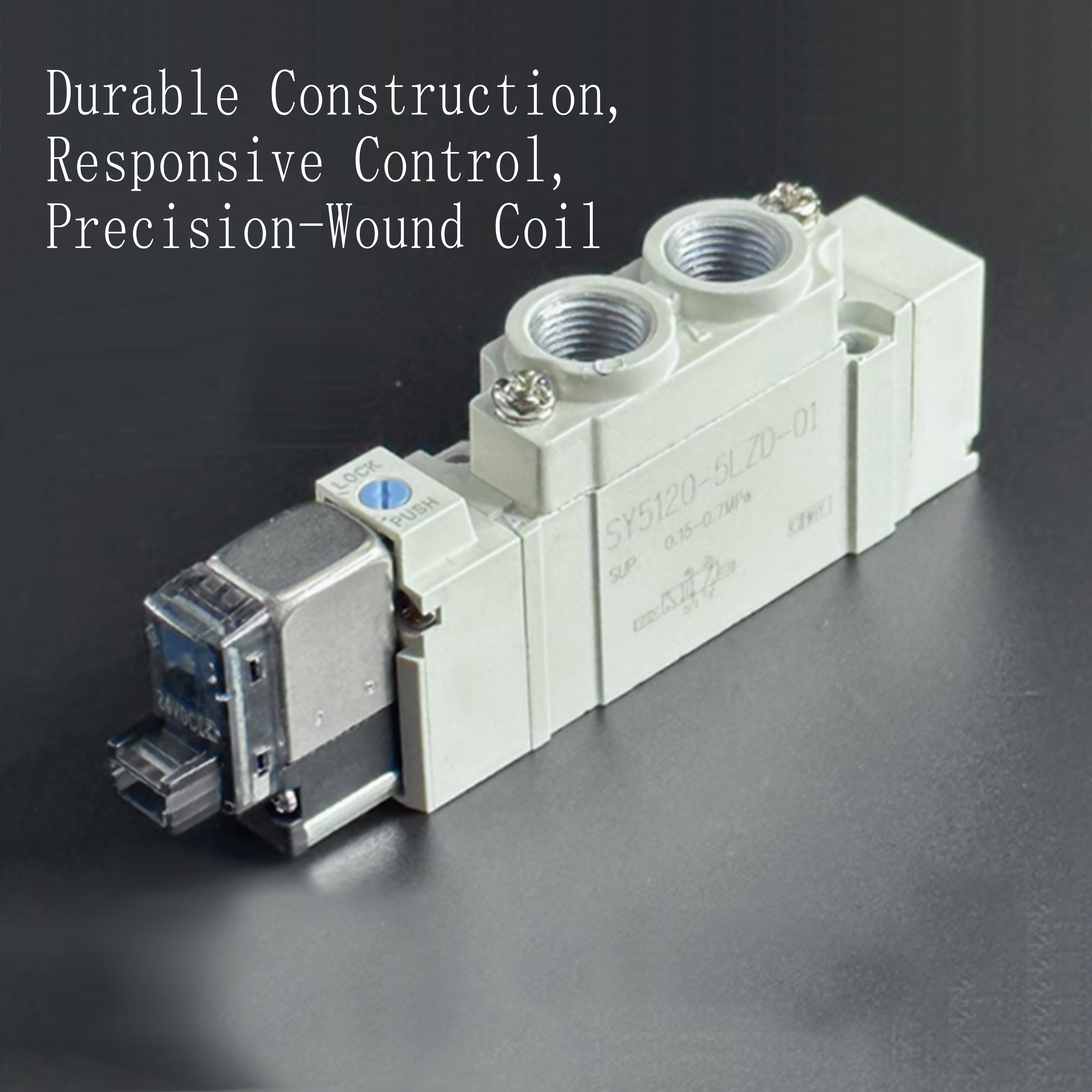

the everyday lifespan of a DC24V pneumatic solenoid valve can vary primarily based on several elements, which include the nice of the valve, the working conditions, and the frequency of use. but, right here are trendy guidelines for the lifespan of these valves:

1. common Lifespan

Mechanical Lifespan: maximum DC24V pneumatic solenoid valves are designed to closing for five to ten million cycles (the wide variety of instances the valve opens and closes). this is based totally on preferred working conditions, in which the valve is used at everyday durations and not subjected to intense stress.

For Valves: top rate valves from installed manufacturers like SMC, Festo, or Parker can from time to time attain 10 to twenty million cycles if used beneath premiere conditions.

2. elements Affecting Lifespan

responsibility Cycle: The valve's responsibility cycle (the ratio of "on" time to "off" time) is a crucial issue in figuring out its lifespan. A valve that operates continuously (a hundred% obligation cycle) may wear out more quickly than one that operates intermittently.

operating stress and Temperature: extreme pressures or temperatures (each high and low) can lessen the lifespan of a solenoid valve. Solenoid valves are typically rated for particular running stress ranges and temperature limits (e.g., -10°C to 50°C), and exceeding those degrees can shorten their operational life.

Medium Cleanliness: If the valve is utilized in systems where the air or gas is infected with dirt, moisture, or debris, it may cause erosion and clogging in the valve, decreasing its lifespan. the use of filtering structures or making sure easy media go with the flow can enlarge the valve’s lifestyles.

Frequency of Use: Valves that are used extra regularly tend to have a shorter lifespan due to the non-stop wear on inner components like seals, diaphragms, and is derived.

Environmental elements: external environmental conditions which include humidity, vibration, or publicity to harsh chemicals or corrosive substances can have an effect on the valve’s sturdiness. for example, a corrosive environment or excessive temperatures can degrade the solenoid coil or different valve parts through the years.

3. upkeep and Care

ordinary maintenance and proper installation can significantly growth the lifespan of a DC24V pneumatic solenoid valve. cleaning the valve periodically, checking for leaks, and making sure it is successfully mounted can assist save you premature failure.

Lubrication (whilst endorsed) and making sure the valve’s seals are intact also are essential for extending the service lifestyles.

4. predicted carrier lifestyles in Years

If used underneath traditional commercial conditions with everyday protection, the lifespan of a pneumatic solenoid valve (specially a DC24V valve, which is commonly used in lots of automation structures) is often between 3 to 10 years, depending at the software and usage patterns.

5. cease of life signs

because the valve nears the give up of its lifespan, you can notice signs and symptoms which includes inconsistent operation, leakage, or failure to open/close properly. those may be indicators that the valve is sporting out and desires restore or replacement.

end

In preferred, the lifespan of a DC24V pneumatic solenoid valve is commonly between 5 to 10 million cycles or about three to ten years, depending on its utilization and protection. proper care, tracking, and deciding on components can notably amplify the operational life of the valve.