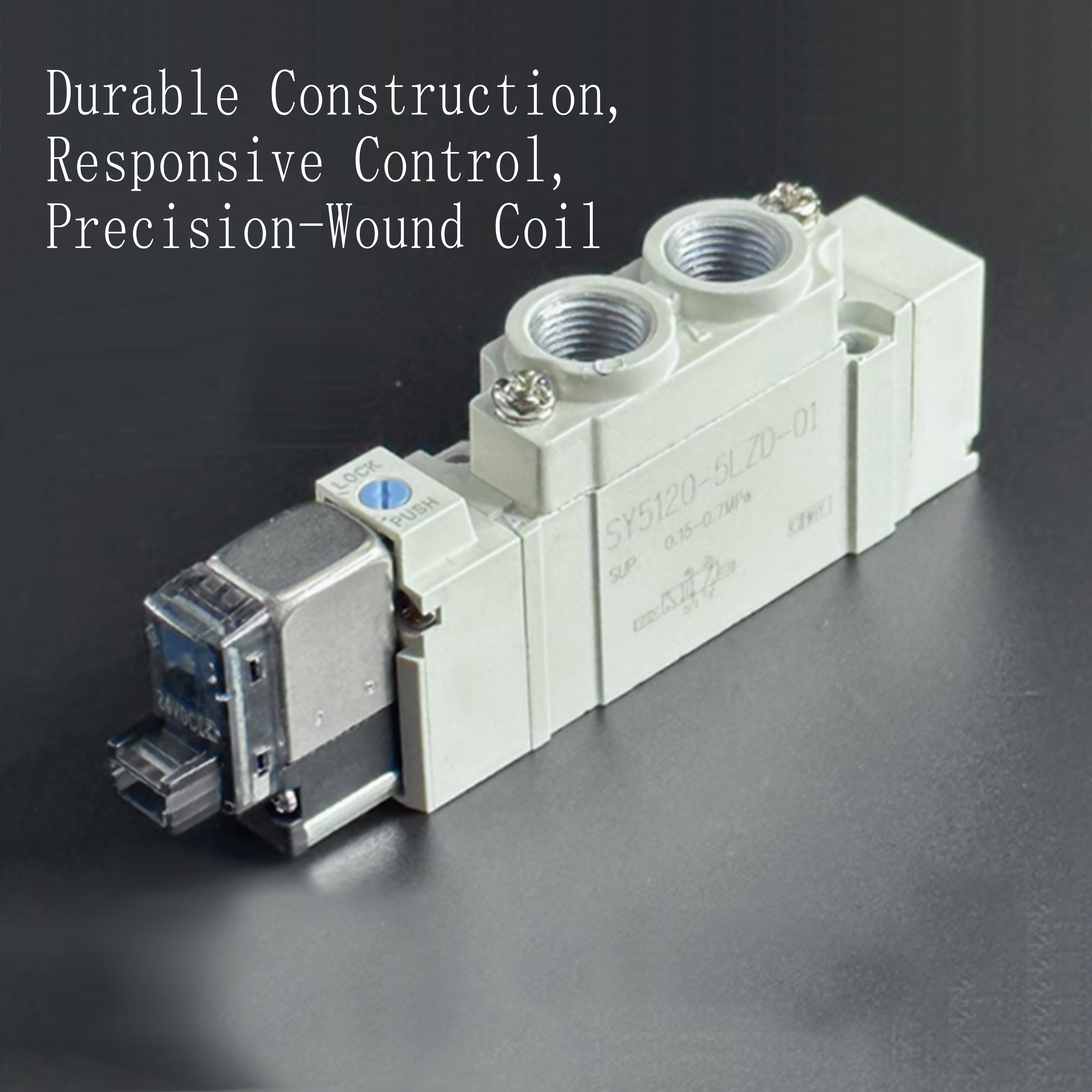

- . A solenoid air manage valve is a sort of valve that makes use of a solenoid (an electromagnetic coil) to control the drift of compressed air in a pneumatic system. it's far broadly used in diverse industries for controlling the operation of pneumatic cylinders, actuators, and different equipment.

the way it Works:

Solenoid Activation:

The solenoid includes a coil of cord that generates a magnetic area when an electrical modern passes thru it.

whilst an electrical signal is applied to the solenoid, the coil becomes magnetized, attracting or repelling an armature or plunger.

movement of the Plunger or Armature:

The magnetic area reasons the armature (a movable aspect) to shift or pass in the valve.

depending at the valve kind, the movement of the armature will both open or near a glide passage inside the valve body or trade the path of airflow.

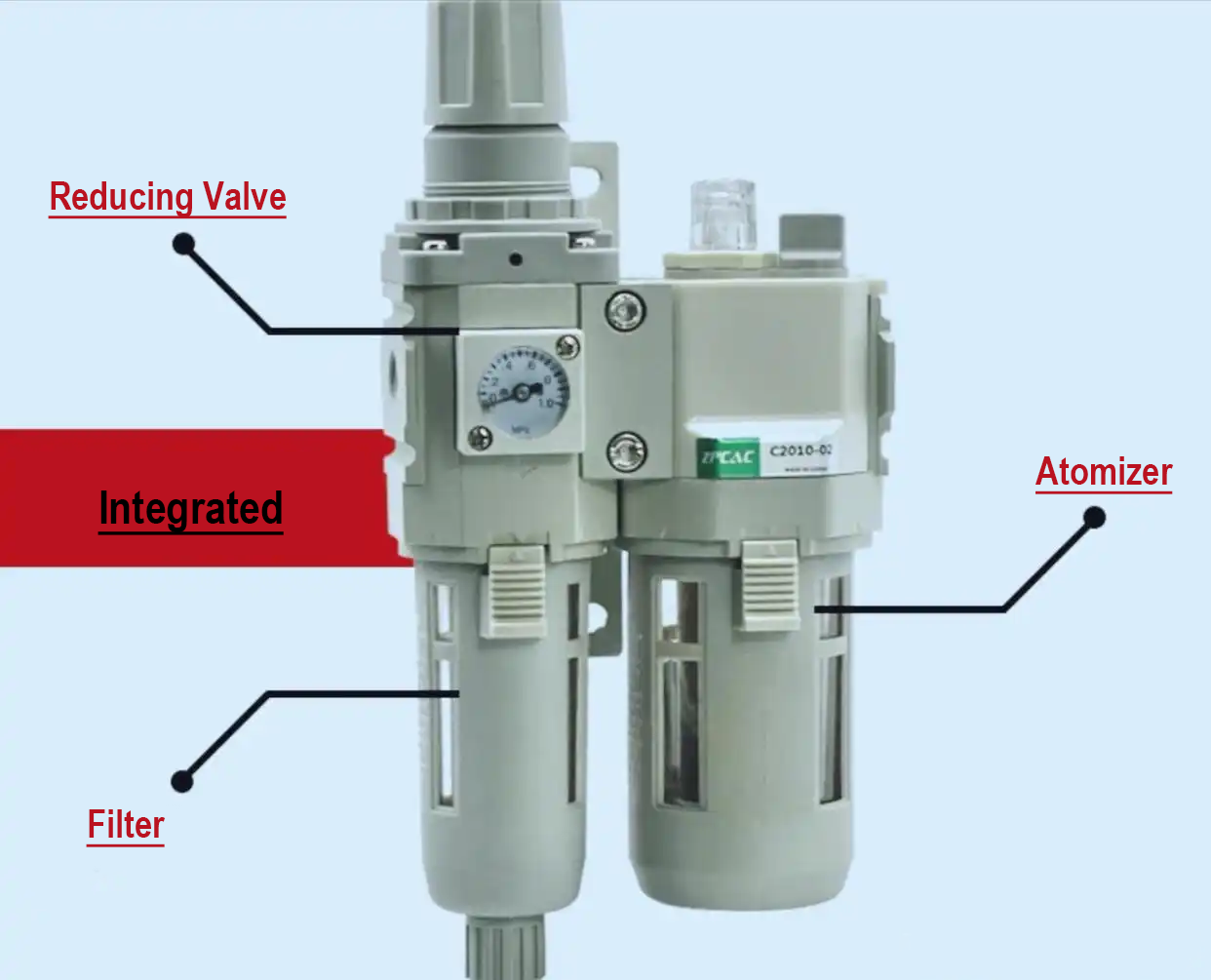

Airflow manage:

The solenoid's motion modifications the location of the internal components (inclusive of a spool, poppet, or diaphragm) within the valve.

This motion opens or closes unique air passages (ports), both permitting compressed air to go with the flow thru or diverting it to a unique path.

kinds of Solenoid Air manipulate Valves:

2-manner Solenoid Valve: This kind has two ports (inlet and outlet) and controls the on/off flow of air. while the solenoid is activated, the valve opens, permitting compressed air to float from the inlet to the outlet. while de-energized, the valve closes, stopping airflow.

three-way Solenoid Valve: It has 3 ports and is generally used to manipulate single-performing cylinders. it is able to permit air to go with the flow in a single route and exhaust air from the cylinder within the different direction, based totally on solenoid activation.

four-way Solenoid Valve: A more complicated valve with four ports, commonly used for controlling double-appearing cylinders. it could trade the direction of airflow to extend or retract the cylinder, with the exhaust air additionally directed to a separate port.

return to Default position:

once the electric signal to the solenoid is removed, the solenoid de-energizes and the armature or plunger returns to its default role, typically with the assist of a spring or any other go back mechanism.

This return motion both closes or reverts the drift route to the unique nation, depending on the valve design.

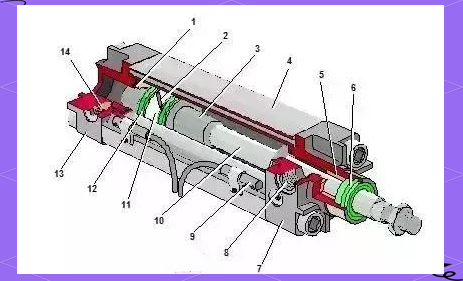

Key additives of a Solenoid Air manage Valve:

Solenoid Coil: Generates the magnetic discipline when energized.

Armature: A movable component this is attracted or repelled by the magnetic area to open or near the valve.

Valve body: includes the go with the flow ports and internal passages that manage the air distribution.

Spool/Poppet/Diaphragm: The inner mechanism that movements to control the glide of air.

Spring (non-obligatory): A go back spring that guarantees the valve returns to its default position whilst the solenoid is de-energized.

running precept (Simplified):

whilst the solenoid is energized (electric modern-day flows via the coil), it creates a magnetic subject that movements the armature.

The armature motion opens or closes unique ports, permitting or preventing the float of compressed air via the valve.

while the solenoid is de-energized (modern-day is reduce off), the armature returns to its authentic role, restoring the valve to its default kingdom.

packages:

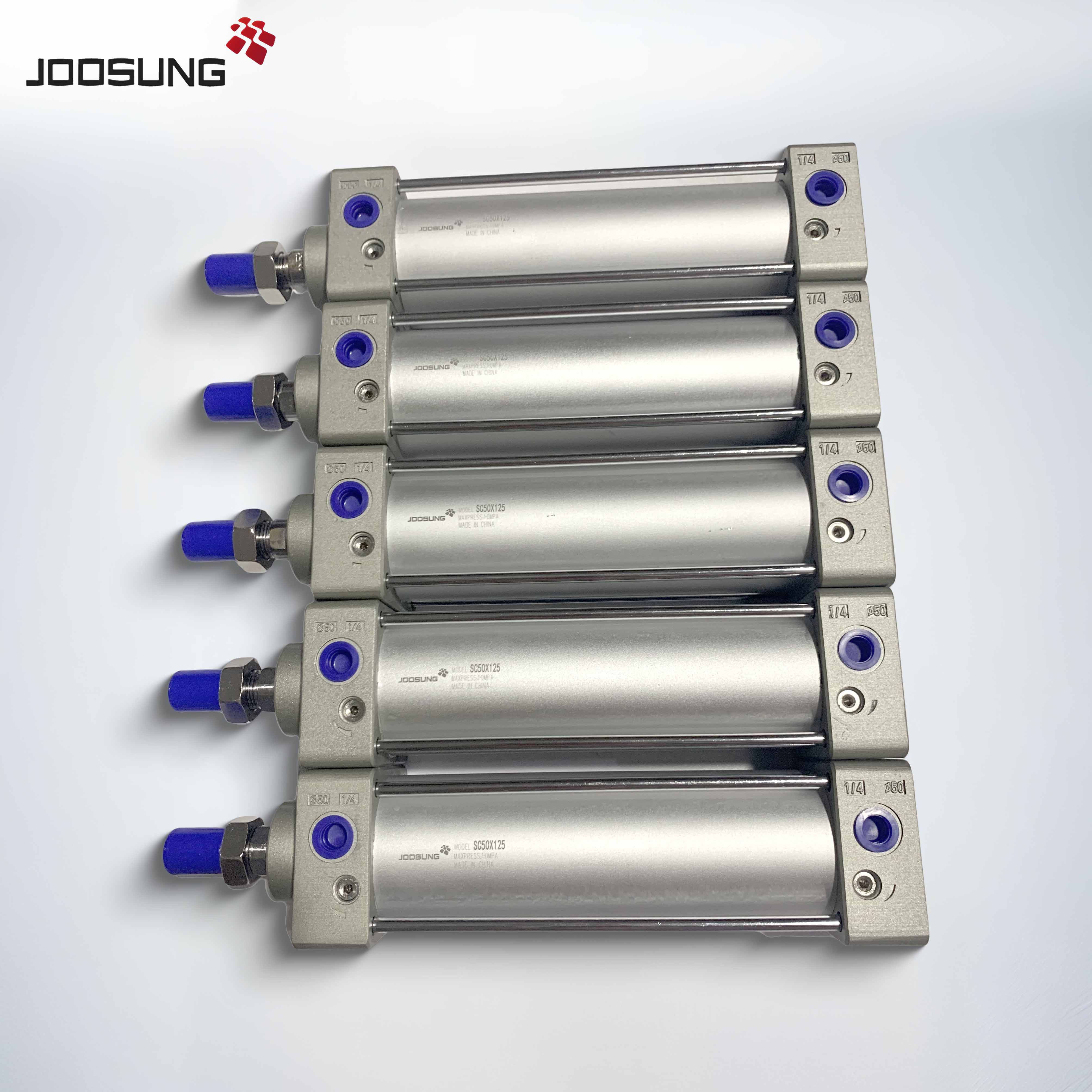

Automation structures: function pneumatic actuators, cylinders, and gear.

production: manipulate equipment and production strains.

HVAC structures: regulate air control in heating, ventilation, and aircon device.

medical devices: manipulate airflow in ventilators, anesthesia machines, and different device.

via the usage of a solenoid to manipulate the movement of internal valve components, solenoid air manage valves offer efficient, dependable, and unique law of air float in various automated structures.