pneumatic cylinder seals are susceptible to corrosion and getting old of the running medium, ensuing in reduced sealing overall performance and gas leakage. the solution is to update the seal in time.

causes and solutions for Pneumatic Cylinder Seal ageing

Pneumatic cylinder seals deteriorate over the years due to various factors, main to leakage, reduced efficiency, and capability device failure. underneath are the primary causes of seal growing old and their corresponding answers.

causes of Seal getting old

put on and Tear from Friction – non-stop operation ends in friction between the seal and cylinder components, steadily degrading the material.

loss of Lubrication – inadequate or mistaken lubrication increases friction and quickens seal wear.

Contaminants in Air deliver – dust, moisture, and oil residues from the compressed air machine can degrade seals.

extreme Temperatures – excessive temperatures purpose seals to harden and crack, whilst low temperatures lead them to brittle.

Chemical publicity – touch with competitive chemicals, oils, or incompatible lubricants can destroy down seal material.

Overpressure and excessive Load – operating the cylinder past its strain or load limits puts more strain on seals, inflicting untimely failure.

incorrect Seal cloth – using seals crafted from incompatible materials for the software environment ends in quicker degradation.

growing old due to Time – Even under best situations, seals certainly degrade over the years due to cloth getting older.

answers to save you Seal aging

Use right Lubrication – practice endorsed lubricants to reduce friction and make bigger seal lifestyles.

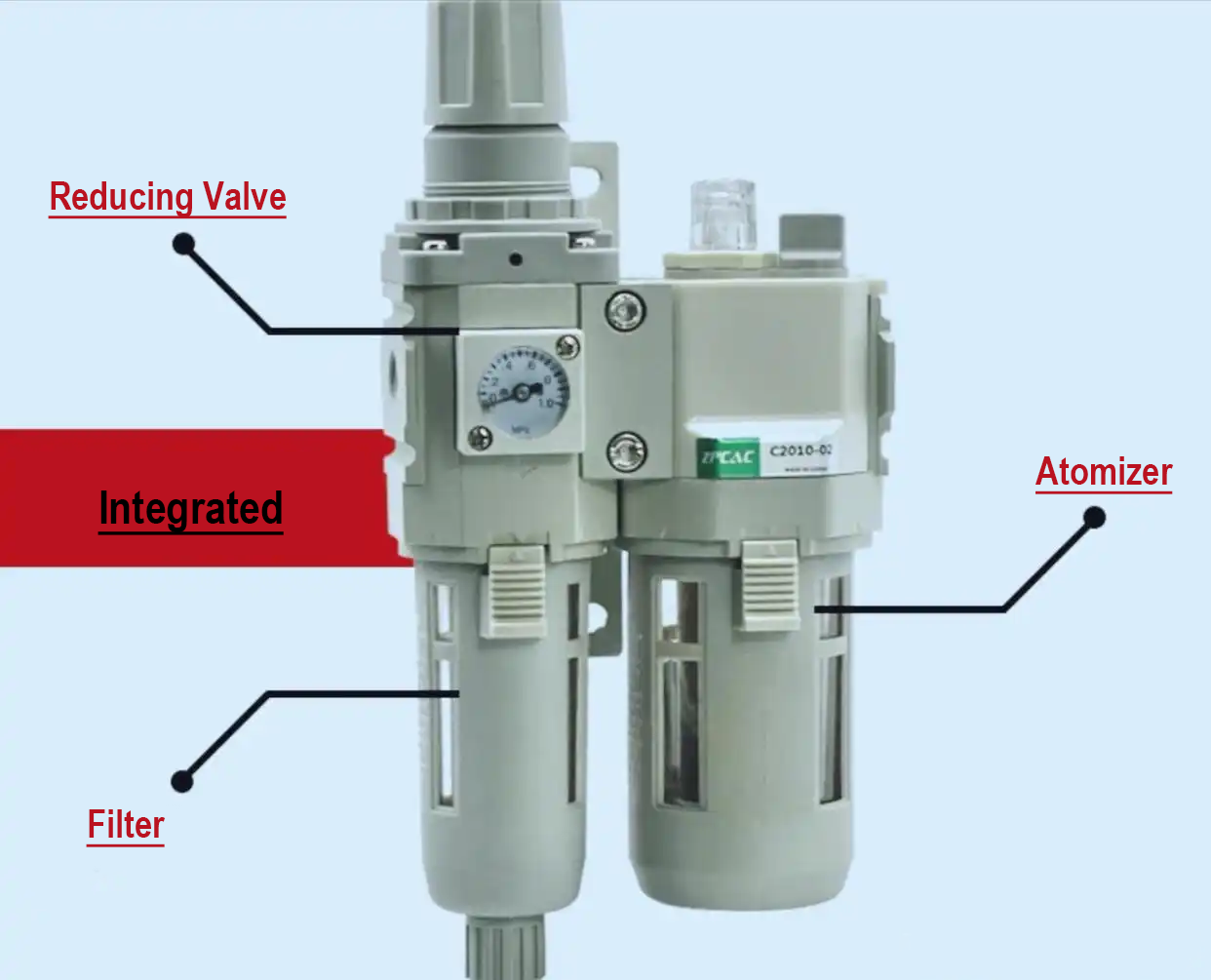

ensure easy, Dry Air supply – set up air filters and dryers to remove contaminants from the compressed air.

pick Temperature-Resistant Seals – pick out seals crafted from high-temperature-resistant substances (e.g., Viton for warmth resistance, polyurethane for cold environments).

Use Chemically compatible Seals – make sure the seal cloth is proof against the chemical substances gift within the system.

keep most useful working situations – keep away from excessive pressure, velocity, or misalignment which could strain seals.

perform regular Inspections – Periodically test seals for symptoms of wear, cracking, or hardening and update them as needed.

replace growing older Seals in Time – even if a seal seems functional, replace it in line with the manufacturer’s recommended lifespan to prevent sudden failures.

via following these preventive measures, you could extensively expand the life of pneumatic cylinder seals and ensure reliable device performance.